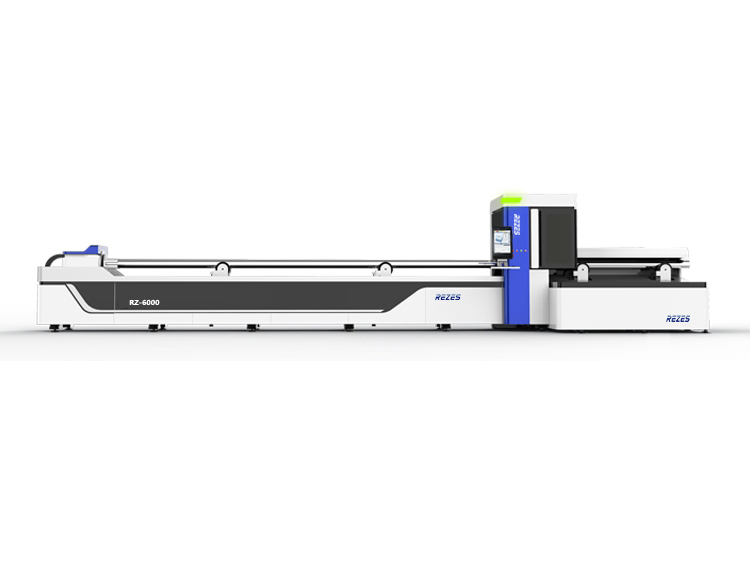

Wholesale Laser Cnc - Double Platform Metal Sheet & Tube Fiber Laser Cutting Machine – Rezes

Wholesale Laser Cnc - Double Platform Metal Sheet & Tube Fiber Laser Cutting Machine – Rezes Detail:

Product Display

Technical parameter

| Application | Laser Cutting | Applicable Material | Metal |

| Cutting Area | 1500mm*3000mm | Laser Type | Fiber Laser |

| Control Software | Cypcut | Laser Head Brand | Raytools |

| Penumatic chuck | 20-350mm | Chuck length | 3m/6m |

| Servo Motor Brand | Yaskawa motor | Machinery Test Report | Provided |

| Graphic Format Supported | AI, PLT, DXF, BMP, Dst, Dwg, DXP | CNC or Not | Yes |

| Key Selling Points | High-accuracy | Warranty of core components | 12 months |

| Mode of Operation | automatic | Positioning Accuracy | ±0.05mm |

| re-positioning accuracy | ±0.03mm | Peak Acceleration | 1.8G |

| Applicable Industries | Hotels, Building Material Shops, Manufacturing Plant | Pneumatical parts | SMC |

| Mode of Operation | continuous wave | Feature | Double platform |

| Cutting Speed | depending on power and thickness | Control Software | Tubepro |

| Cutting Thickness | 0-50mm | Guiderail Brand | HIWIN |

| Electrical parts | schneider | Warranty time | 3 years |

Maintenance of Machine

1.Cooling system maintenance

The water inside the water cooler needs to be replaced regularly, and the frequency of replacement is usually one month. The water-cooling machine is responsible for cooling the laser and other parts of the equipment as circulating water. It is easy to form scale when the water quality is used for a long time, thereby blocking the waterway and causing the water flow to decrease and reducing the cooling effect. Therefore, regular water replacement is the primary problem. Water should be distilled as much as possible. If there is no condition, deionized water can be selected. Each manufacturer has requirements for water quality, and it is important to meet the requirements. Otherwise, the use of unqualified water quality for a long time will cause internal fouling of the laser.

2.Dust removal system maintenance

The long-term use of the fan will cause a lot of solid dust to accumulate inside the fan, which will cause a lot of noise and is not conducive to exhaust and deodorization. When there is insufficient suction of the fan, the power supply is first turned off, the air inlet pipe and the air outlet pipe on the fan are removed, the dust inside is removed, and then the fan is inverted, and the fan blades are pulled up until it is clean. Then install the fan.

3.Optical system maintenance

The laser is reflected from the lens and focused out of the laser head. After the equipment is running for a period of time, the surface of the lens will be coated with some dust, which will greatly affect the reflectivity of the lens and the transmittance of the lens, resulting in a decrease in the power of the laser. Dust. However, be careful when cleaning. The lens is a fragile item. You should use it with a light object or a hard object to touch the lens.

The steps for cleaning the lens and the precautions are as follows: Firstly, use a cotton wool and ethanol to carefully wipe along the center of the lens to the edge. The lens needs to be wiped gently. The surface coating should not be damaged. During the wiping process, gently handle it to prevent it from falling. When installing the focusing mirror, be sure to keep the concave side facing down. In addition, the number of ultra-high-speed perforations is usually reduced as much as possible, and the use of conventional perforations can extend the life of the focusing mirror.

4. Transmission system maintenance

In a laser cutting machine, the transmission system is equivalent to a person’s heel and foot. The transmission system directly affects the normal operation and service life of the equipment. The laser cutting machine will generate smoke during the long-term cutting process. The fine dust will enter the equipment through the dust cover and attach to the rail rack. The long-term accumulation will increase the guide rail teeth. The wear of the strip, the rack guide is originally a relatively sophisticated accessory, and the long time will cause damage to the slider and the gear. Therefore, the rail rack should be regularly cleaned by dust removal. After cleaning the dust attached to the rack rack, the rack is greased and the rail is lubricated with lubricating oil.

Machine Video

Metal Sheet & Tube Fiber Laser Cutting Machine

Cutting samples

Product detail pictures:

Related Product Guide:

We consistently carry out our spirit of Innovation bringing development, Highly-quality ensuring subsistence, Management promoting benefit, Credit attracting customers for Wholesale Laser Cnc - Double Platform Metal Sheet & Tube Fiber Laser Cutting Machine – Rezes , The product will supply to all over the world, such as: Canberra, Russia, Argentina, We always stick to the tenet of sincerity, high quality, high efficiency, innovation. With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.