Ultra-Large Format Sheet Metal Fiber Laser Cutting Machine

Product Display

Technical parameter

| Application | Laser cutting | Applicable Material | Metals |

| Laser Source Brand | Raycus/MAX/RECI | Cutting Area | 6000*3000/12000 * 3000 /20000* 4000 |

| Positioning accuracy | ±0.1/10000mm | Repeated positioning | ±0.05mm |

| Power parameters | 3 phase 380V 50Hz | Cutting Depth | subject to material |

| Graphic Format Supported | AI, PLT, DXF, BMP, Dst, Dwg, DXP | CNC or Not | Yes |

| X and Y axis maximum moving speed | 80m/min | Certification | CE, ISO9001 |

| Mode of Operation | Manual or Automatic |

Maximum acceleration |

0.6G |

| Protection Level of Total Power Supply | IP54 | Cooling system | water cooling |

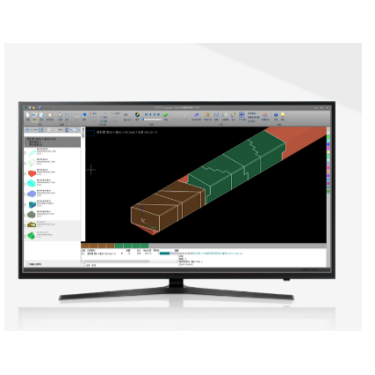

| Control System | Cypcut/Raytools | Software | Hyput 8000 |

| Mode of Operation | Continuous wave | Feature | Low maintenance |

| Configuration | overall design | Video outgoing inspection | Provided |

| Place of Origin | Jinan,Shandong Province | Warranty time | 3 years |

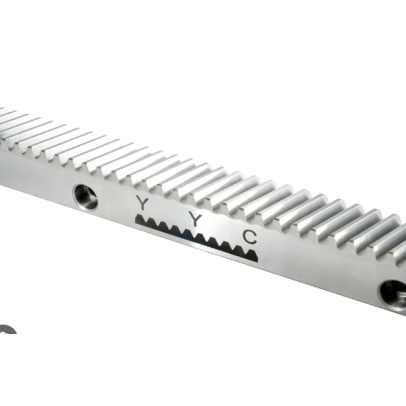

Advantages of bevel cutting with laser cutting machine

1、Increased processing efficiency. Compared with the traditional processing method, laser cutting machine bevel cutting can be in place at one time, without the second cutting and grinding, the efficiency of more than 75%.

2、Improved bevel surface quality. Traditional processing garden arc bevel, the surface quality is poor, can not use automatic welding, laser cutting machine bevel cutting can be directly welded.

3、Stable quality of batch processing. Affected by operator cutting fatigue, traditional cutting bevel quality is unstable and low efficiency. Using laser cutting machine cutting, small-scale prototype can be made, after qualified can be mass-produced. Effectively ensure the bevel cutting size and precision of the workpiece and continuous cutting.

4、Reduce bevel processing cost. The traditional way of bevel processing requires a lot of manual grinding, using laser cutting machine bevel cutting, can be mass production, effectively reduce labor costs

and time investment

Through the bevel cutting process, the workpiece cutting section is smooth and flat, and can be seamlessly dovetailed with each other, which greatly meets the demand of workpiece bevel welding.

Cutting samples

Service

---Pre-Sales Service:

Free Pre-Sales Consulting/Free Sample larking

REZES Laser offer 12 hours quick pre-sales response and free consulting, Any kind of technical support are

available for users.

Free Sample Making is available.

Free Sample Testing is available.

We offer progressing solution design to all the distributor and users.

---After-sales Services :

1.3 year guarantee for fiber laser cutting machine

2.Full technical support\ by e-mail, call and video

3.Lifelong maintenance and spare parts supply.

4. Free design of fixtures as customers required.

5. Free training installation and operation for the staffs.

FAQ

1. Q:Why should we choose you?

A: lf you choose us, you will get top quality,best service,reasonable price and reliable warranty.

2.Q:l'm not familiar with the machine,how to choose?

A: Just tell us materials, thickness and working size, l will recommend the suitable machine.

3. How to operate the machine?

A: We will deliver English manual and video with the machine to you.lif you still need our further help,please contact us.

4.Q:Can l get the sample to check quality of machine?

A: Of course.Please provide your logo or design to us, free samples can be provided for you.

5.Q:Can the machine be customized according my requirements?

A: Sure,we have a strong technical team and have rich experience. Our goal is to make you satisfied.

6.Q:Can you arrange the shipment for us?

A: Of course.We can arrange the shipment for our clients accordingly by sea and air. Trading terms FOB, ClF, CFR are available.