RECI Laser Tube 80W, 100W, 130W, 150W, 180W for sale

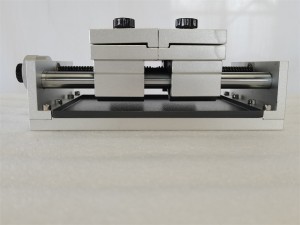

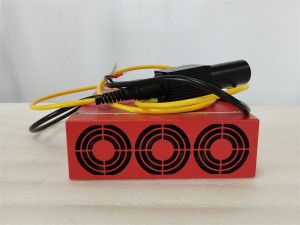

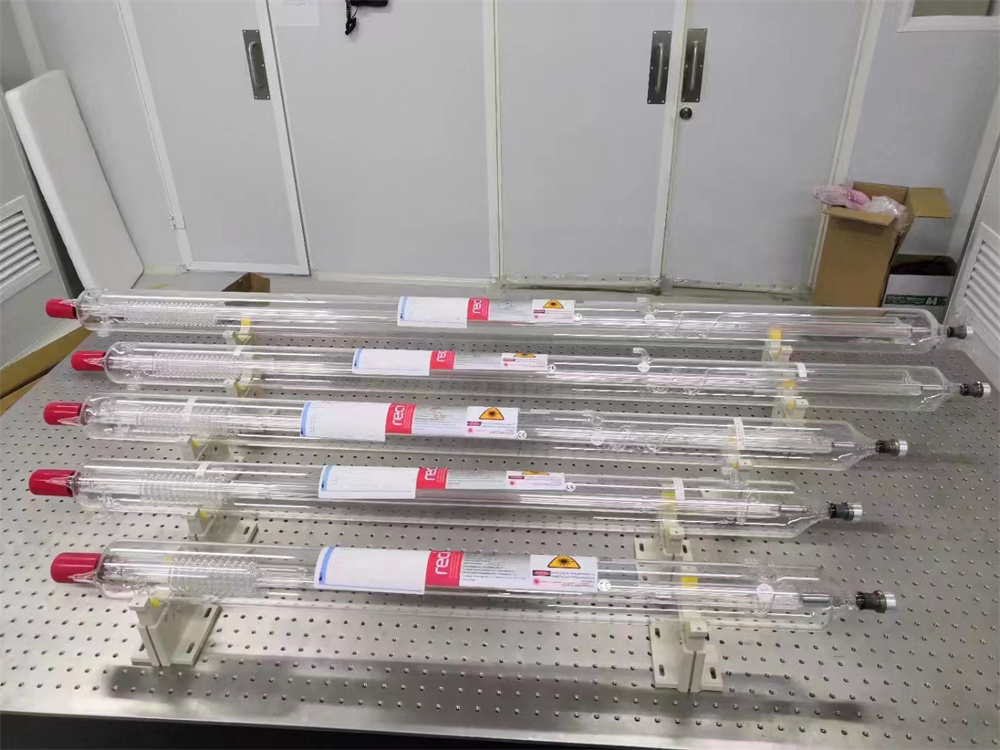

Product Display

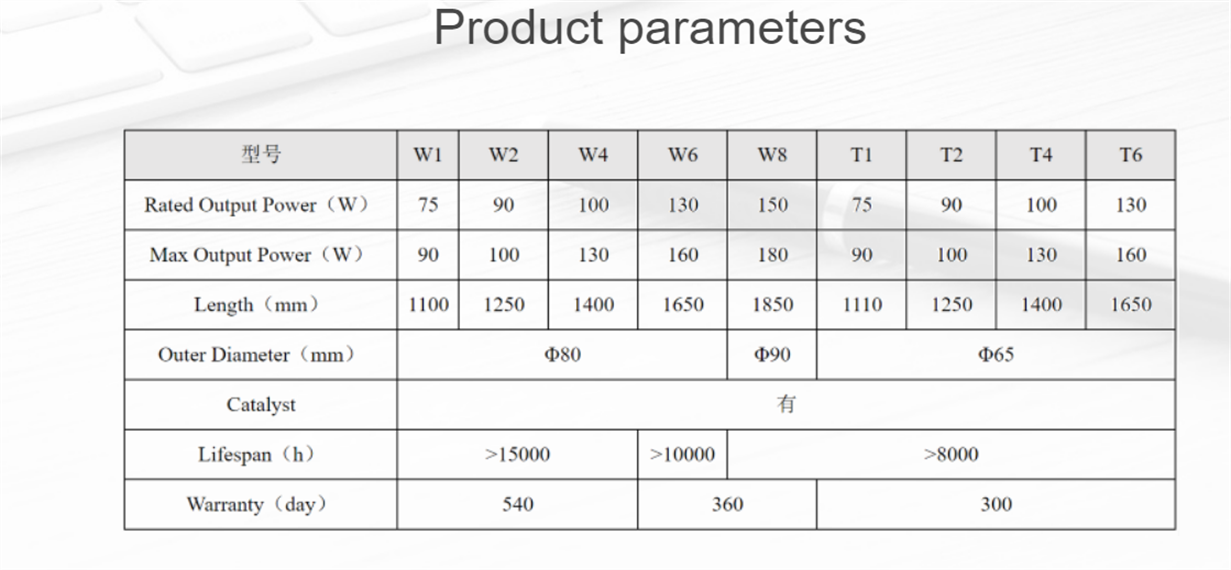

Product parameter

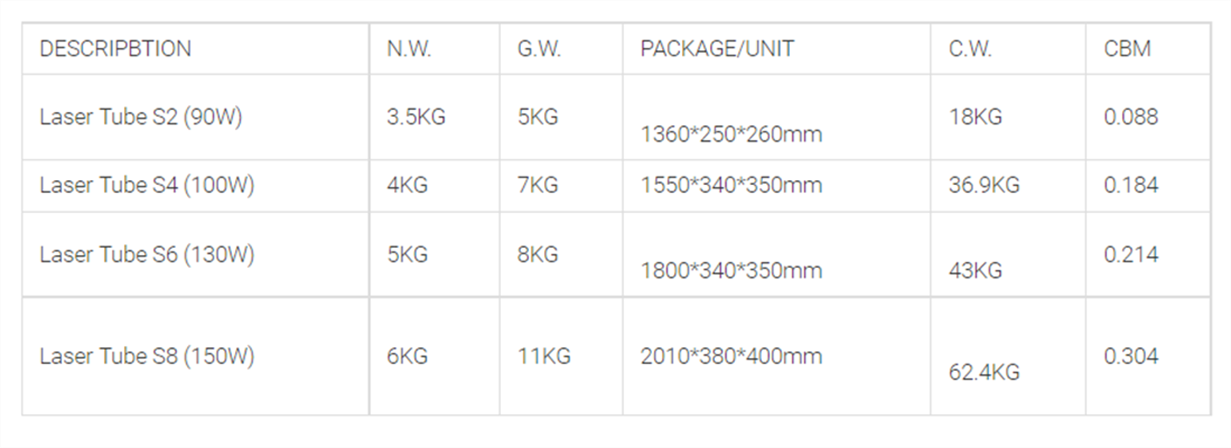

Package of laser tube

Cutting parameter

|

Cutting Power Speed(mm/s) Material |

60W |

80W |

100W |

150W |

|

Acrylic 3mm |

6-10 70%-90% 20-25 |

10-15 50%-80% 50-55 |

10-15 40%-80% 55-60 |

10-15 30%-80% 60-70 |

|

Acrylic 5mm |

6-8 60%-80% 8-10 |

8-15 60%-90% 15-20 |

8-15 70%-90% 20-25 |

8-15 60%-90% 25-30 |

|

Acrylic 10mm |

2 60%-85% 3-4 |

3-5 60%-85% 6-8 |

4-6 70%-90% 6-9 |

5-8 70%-90% 10 |

|

Acrylic 30mm |

|

0.4-0.6 80%-95% 0.7-0.9 |

0.4-0.8 80%-95% 0.8-1.0 |

0.6-1.0 80%-95% 0.8-1.2 |

|

Plywood 5mm |

10-20 60%-90% |

40-60 60%-85% |

50-70 65%-85%

|

50-80 50%-90% |

|

Plywood 12mm |

|

Not recommend |

5-8 70%-95% |

8-12 30%-90% |

|

MDF 6mm |

|

6-10 60%-85% |

8-15 50%-95% |

15-20 50%-90% |

|

MDF 15mm |

|

Not recommend |

2-3 80%-90% |

3-4 80%-90% |

|

Foam 2cm |

Not recommend |

50-60 75%-85% |

60-80 75%-85% |

80-100 70%-90% |

|

Leather |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

|

Fabric |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

|

Cloth (one layer) |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

|

Thin Carpet |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

|

Spongy fabric |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

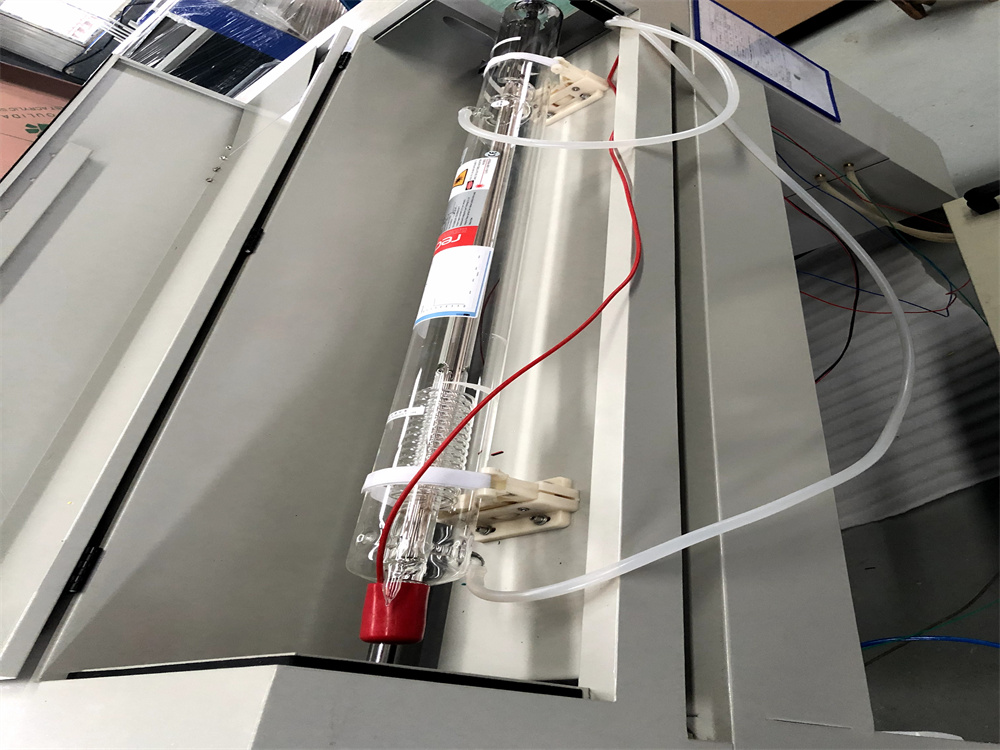

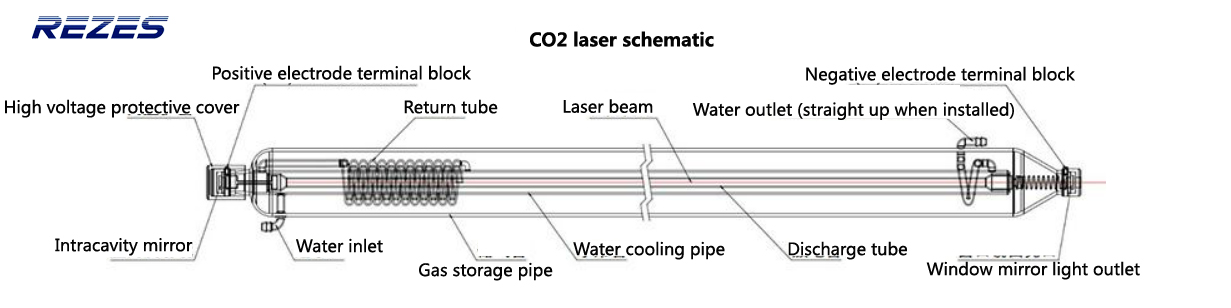

Structure of Co2 laser tube

More parameter

| Item | Value |

| Condition | New |

| Warranty | 18 months |

| Place of Origin | China |

| Spare Parts Type | laser tube |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | New Product 2022 |

| Brand Name | RECI |

| Key Selling Points | High Safety Level |

| Showroom Location | none |

| Applicable Industries | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, restaurant, HOME USE, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company |

| Local Service Location | none |

| Product name | RECI laser tube |

| Laser type | co2 |

| Diameter | 80mm |

| Tube length | 1250mm |

| Warranty period | 18 months |

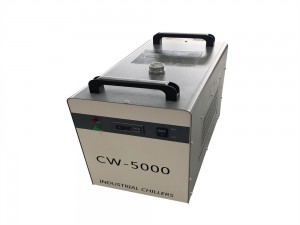

How to Maintain Your CO2 Laser Tube?

1. Must keep circulating water clean.If you find water becomes dirty,you must replace cooling water .And the cooling water must not be too cold or too hot.Because the laser tube is easy to be broken .It is better to keep cooling water temperature between 18 to 25 degrees.The water temperature exceeds 30 degrees , the effect will gradually decrease the laser power. Laser tube cooling water should not have bubbles.

2. Laser tube with sediment for long time, it is better to remove the laser tube and clean it,then install again.

3. Keep mirrors and lens clearly .If you use laser machine in a very terrible environment,need professionals use alcohol to wipe the lens.

4. According to different laser power to set current.If the current is too high,it will shorten the service life of laser tube. Maintain your CO2 laser tube well can not only protect the laser cutting machine, but also help you improve the working efficiency. So just pay attention to learn it.

5. How can I store the laser tubes when I do not use it?

The cooling liquid must run out in storage or transportation; The output must be covered with a dust-proof plastic wrap; The storage temperature should be kept between 2-40°C and the humidity between 10-60%.

Package of laser tube

Wooden package

Carton Package