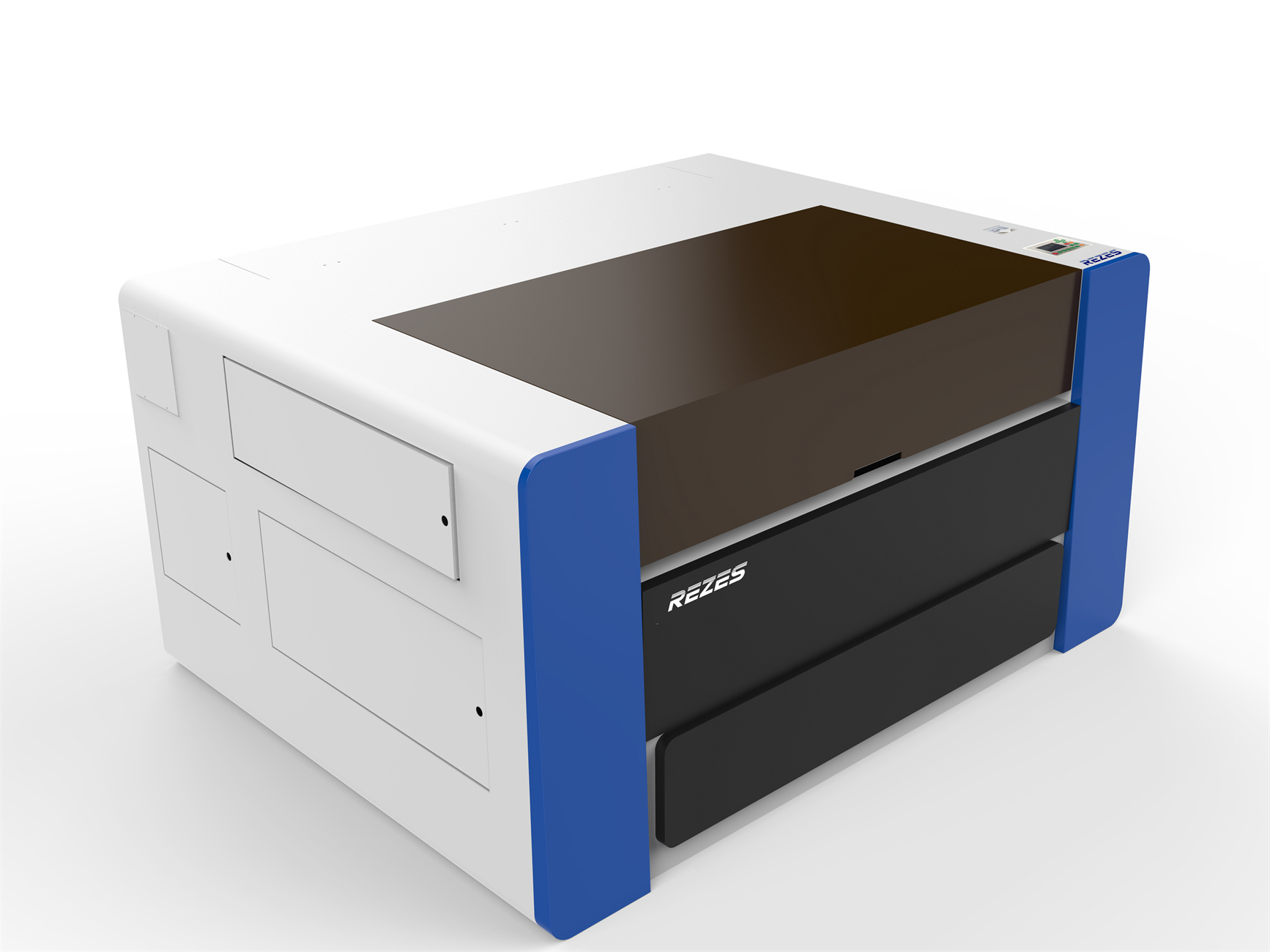

OEM Manufacturer Mix Laser Cutting Machine - Laser Cleaning Machine – Rezes

OEM Manufacturer Mix Laser Cutting Machine - Laser Cleaning Machine – Rezes Detail:

Product Display

Technical parameter

|

Condition |

New |

Core Components |

Laser Source |

|

Usage |

Clean Metal |

Max. Output Power |

1500W, 1000W, 2000W |

|

Working Environment |

Flat, No Vibration, No Impact |

Cnc Or Not |

Yes |

|

Clean Width |

10-100mm |

Cooling Method |

Water Cooling |

|

Cleaning Type |

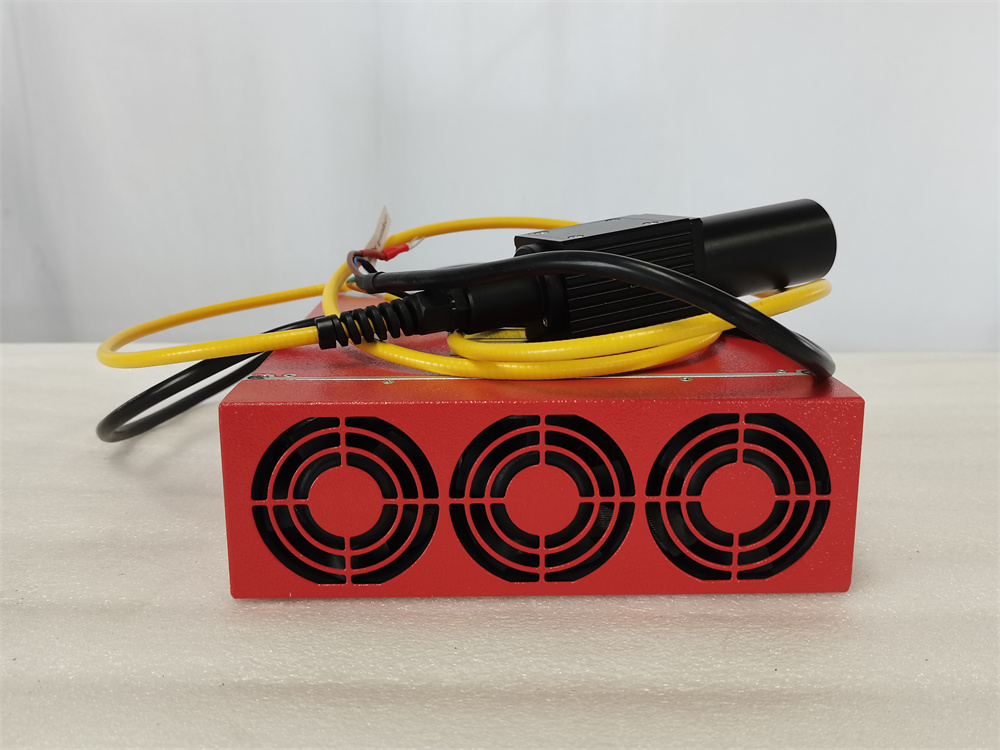

Handheld |

Laser Power |

1000w/ 1500w/ 2000w |

|

Weight (Kg) |

300 Kg |

Certification |

Ce, Iso9001 |

|

Clean Way |

Non-Touch Laser Cleaning |

Key Selling Points |

High-Accuracy |

|

Function |

Metal Part Laser Welding |

Fiber Length |

≥10m |

|

Applicable Industries |

Hotels, Garment Shops, Building Material Shops |

Core Components |

Laser Source, Laser Head, Double Wobble Lase Head |

|

Laser Source Brand |

Raycus/Max/Ipg |

After Warranty Service |

Online Support |

|

Focal Length |

Focal Length Of Firld Mirror(F160,254,330.) |

Maximum Pulse Energy |

1.5Mj |

|

Supply Voltage |

48V |

Graphic Format Supported |

Ai, Plt, Dxf, Dwg, Dxp |

|

Place Of Origin |

Jinan,Shandong Province |

Warranty Time |

3 Years |

The machine video

Laser cleaning machine cleaning rust:

The advantage of laser cleaning machine

1. Environmental protection: Laser cleaning is a “green” cleaning method that does not require the use of any chemicals and cleaning fluids. The cleaned waste is basically solid powder, small in size, easy to store, recyclable, and has no photochemical reaction. No pollution will occur.

2. Effect: The non-abrasive, non-contact and non-thermal effect of laser cleaning will not destroy the substrate, so these problems can be solved easily.

3. Control: The laser can be transmitted through the optical fiber, cooperate with the robot , and can easily realize long-distance operation. It can clean the parts that are not easy to reach by traditional methods. This can ensure the safety of personnel when used in some dangerous places.

4. Convenience: Laser cleaning can remove various types of pollutants on the surface of various materials, and achieve a cleanliness that cannot be achieved by conventional cleaning. Furthermore, contaminants on the surface of the material can be selectively cleaned without damaging the surface of the material.

5. Precision: It can clean up micron-level pollution particles and realize controllable fine cleaning, which is suitable for the cleaning of precision instruments and precision parts.

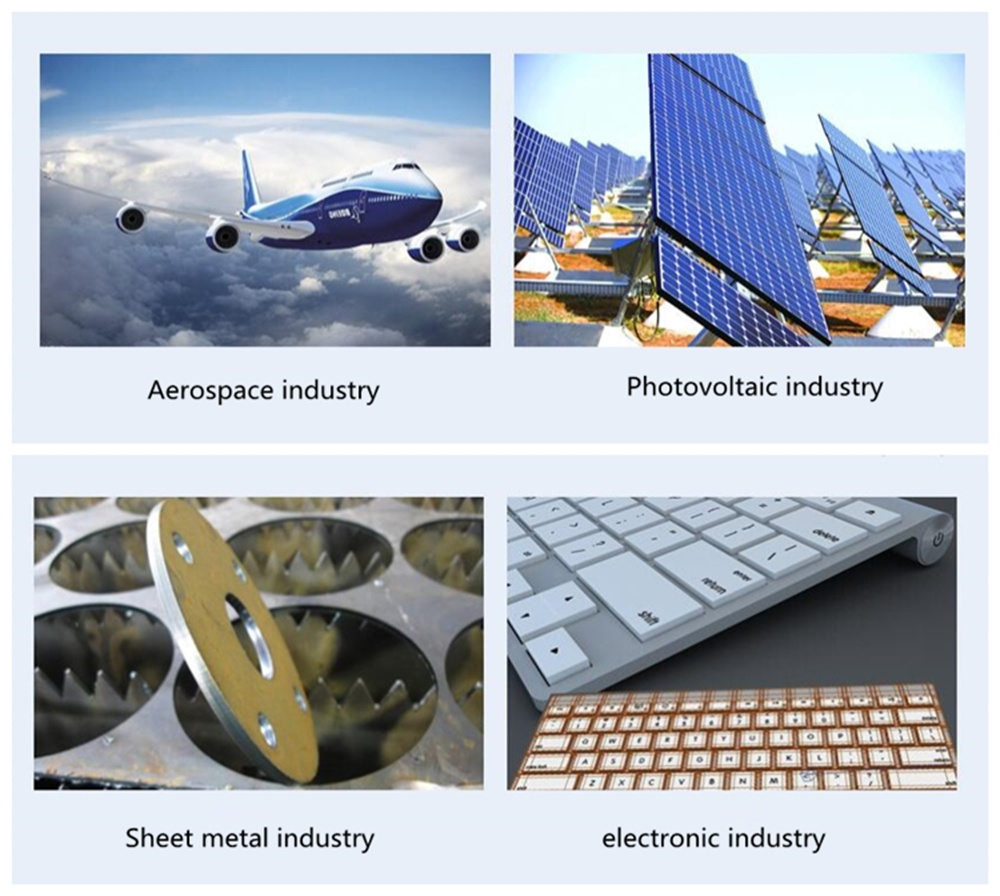

Applicable material

As a new cleaning method, laser cleaning machine has a wide range of industrial applications:

1. Rust removal and surface polishing

On the one hand, metals exposed to moist air react chemically with water to form ferrous oxide. Gradually, this metal will rust. Rusting can reduce the quality of the metal, making it unsuitable for many machining situations.

On the other hand, during heat treatment, an oxide layer will appear on the metal surface. This oxide layer changes the color of the metal surface and prevents further processing of the metal.

Both cases require a laser cleaner to get the metal back to normal.

2. Anode assembly cleaning

If there is dirt or other contaminants on the anode assembly, the resistance of the anode increases, causing the battery to drain energy faster and ultimately shorten its lifespan.

3. Preparation of metal welds

For better adhesion and better weld quality, the surfaces of the two metals need to be cleaned before welding. If not cleaned, joints are prone to breakage and wear out quickly.

4. Paint Removal

Laser cleaning can be used to remove paint in industries such as automotive, maintaining the integrity of the base material.

Cutting sample

Comparison before and after cleaning

Product detail pictures:

Related Product Guide:

We insist on offering high quality production with good business concept, honest sales and the best and fast service. it will bring you not only the high quality product and huge profit, but the most significant is to occupy the endless market for OEM Manufacturer Mix Laser Cutting Machine - Laser Cleaning Machine – Rezes , The product will supply to all over the world, such as: Marseille, US, Japan, Due to the changing trends in this field, we involve ourselves into products trade with dedicated efforts and managerial excellence. We maintain timely delivery schedules, innovative designs, quality and transparency for our customers. Our moto is to deliver quality products within stipulated time.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.