Difference :

1,The laser wavelength of fiber laser marking machine is 1064nm. The UV laser marking machine uses a UV laser with a wavelength of 355nm.

2, The working principle is different

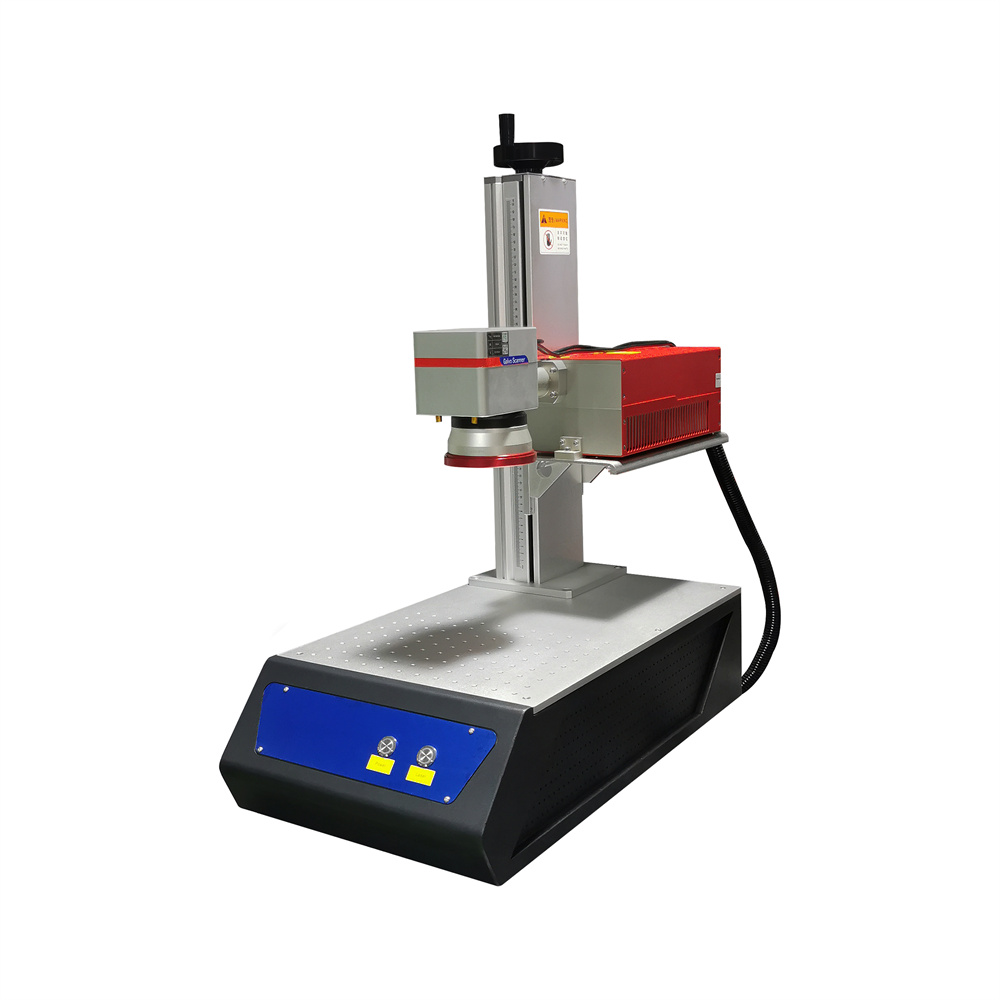

Fiber laser marking machines use laser beams to make permanent marks on the surface of various materials. The function of marking is to expose the deep material through the evaporation of the surface material, or "carve" traces through the physical changes of the surface material caused by light energy, or to display the pattern, text, and barcode to be etched by burning part of the material through light energy and other types of graphics.

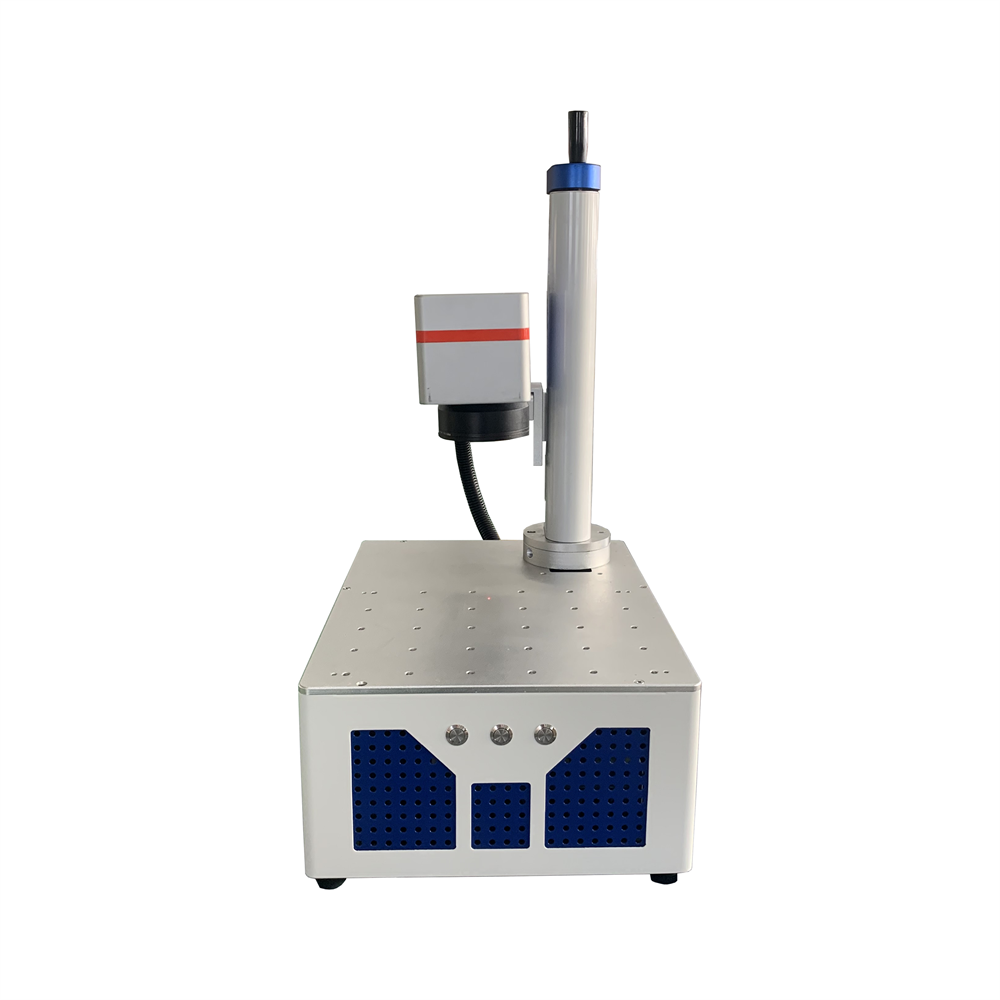

Ultraviolet laser marking machine is a series of laser marking machines, so the principle is similar to that of laser marking machines, which use laser beams to make permanent marks on the surface of various materials. The function of marking is to directly break the molecular chain of the material through the short-wave laser (different from the evaporation of the surface material produced by the long-wave laser to reveal the deep material), revealing the pattern and text to be processed.

4. Different fields of application

Fiber laser marking machine is basically suitable for laser marking on various metal surfaces. Due to the heat generated by its beam, it is not suitable for high-precision marking of special materials. like:

Widely used in integrated circuit chips, computer accessories, industrial bearings, watches, electronic communication products, aerospace devices, various auto parts, home appliances, hardware tools, molds, wires and cables, food packaging, jewelry, tobacco, military, etc. Graphic marking, batch production line operation.

Ultraviolet laser marking machine: especially suitable for the high-end market of fine processing. like:

A. Cosmetics, medicines, accessories and other polymer material packaging bottles have good surface marking effects, strong cleaning power, better than inkjet coding, and no pollution;

B. Marking and scribing of flexible pcb boards; processing of micro-holes and blind holes on silicon wafers;

C. LCD liquid crystal glass two-dimensional code marking, glass surface drilling, metal surface coating marking, plastic buttons, electronic components, gifts, communication equipment, building materials, etc.

Post time: Feb-20-2023