Manufacturer Of Fiber Laser Marking Machine - Metal&Nonmetal Laser Cutting Machine – Rezes

Manufacturer Of Fiber Laser Marking Machine - Metal&Nonmetal Laser Cutting Machine – Rezes Detail:

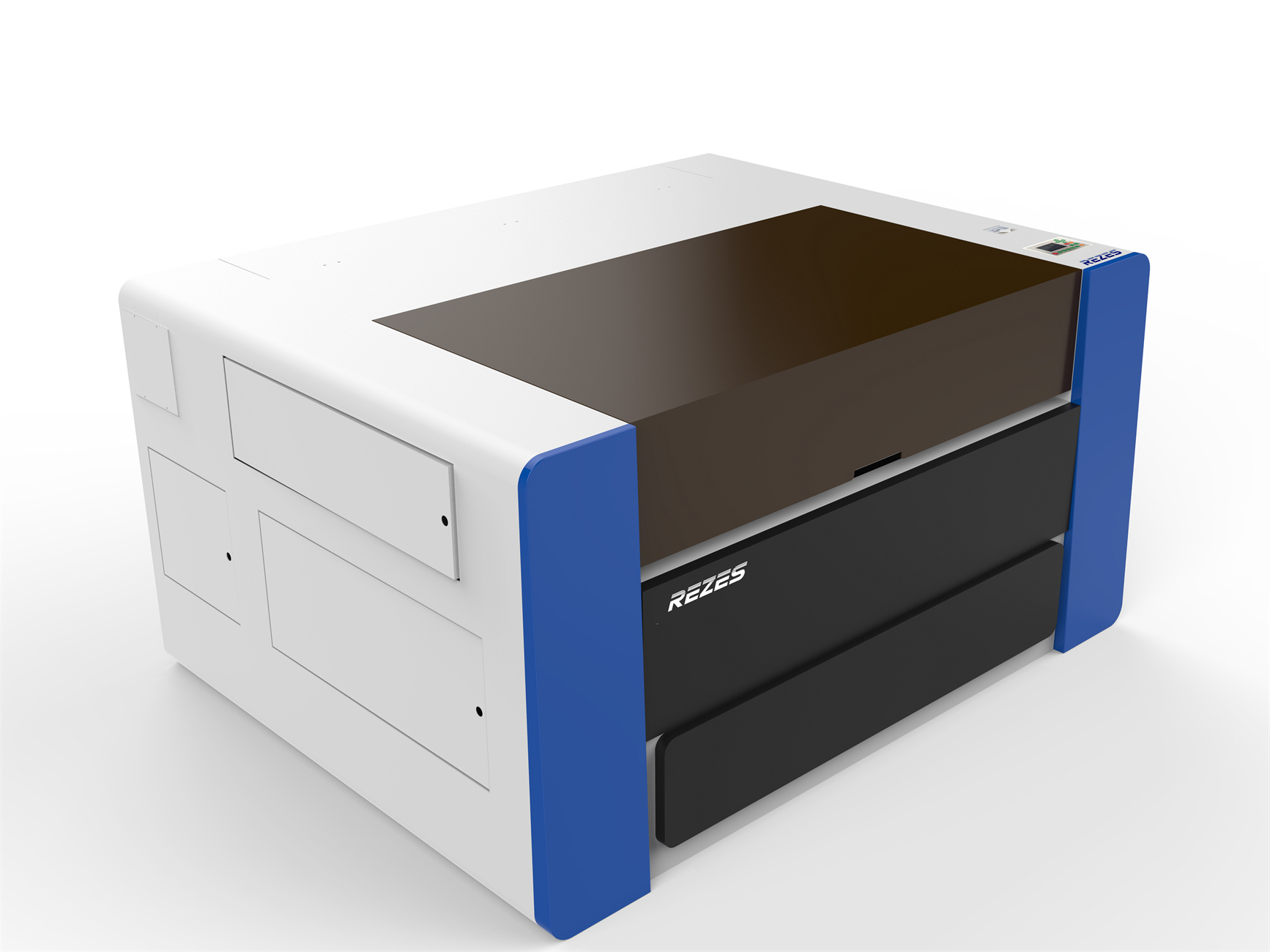

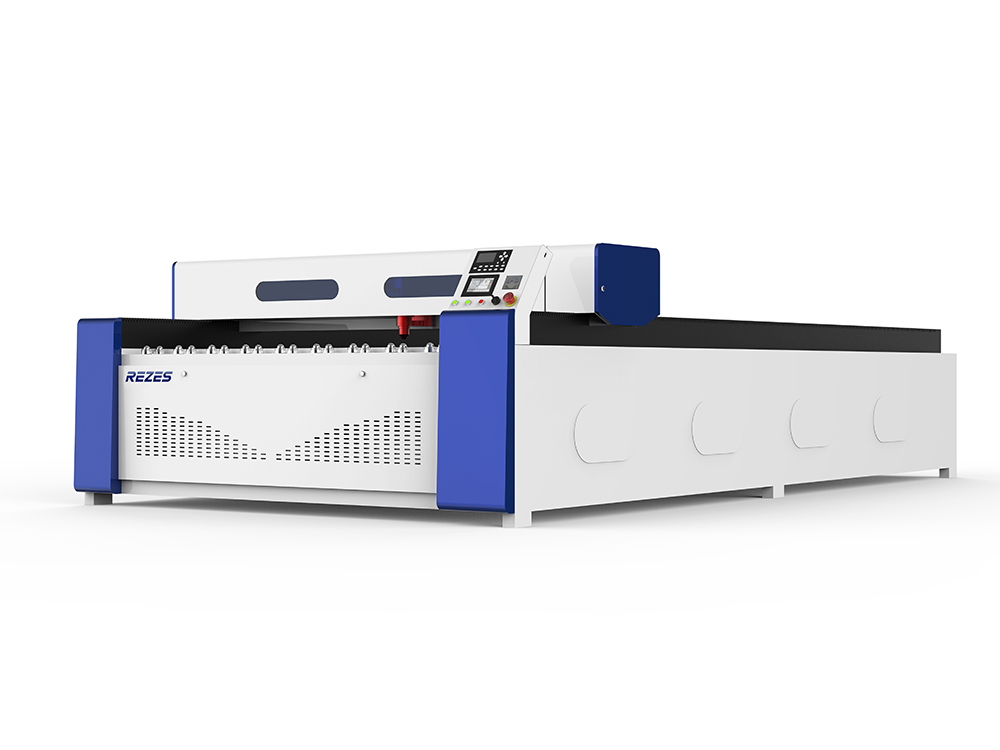

Product Display

Technical parameter

|

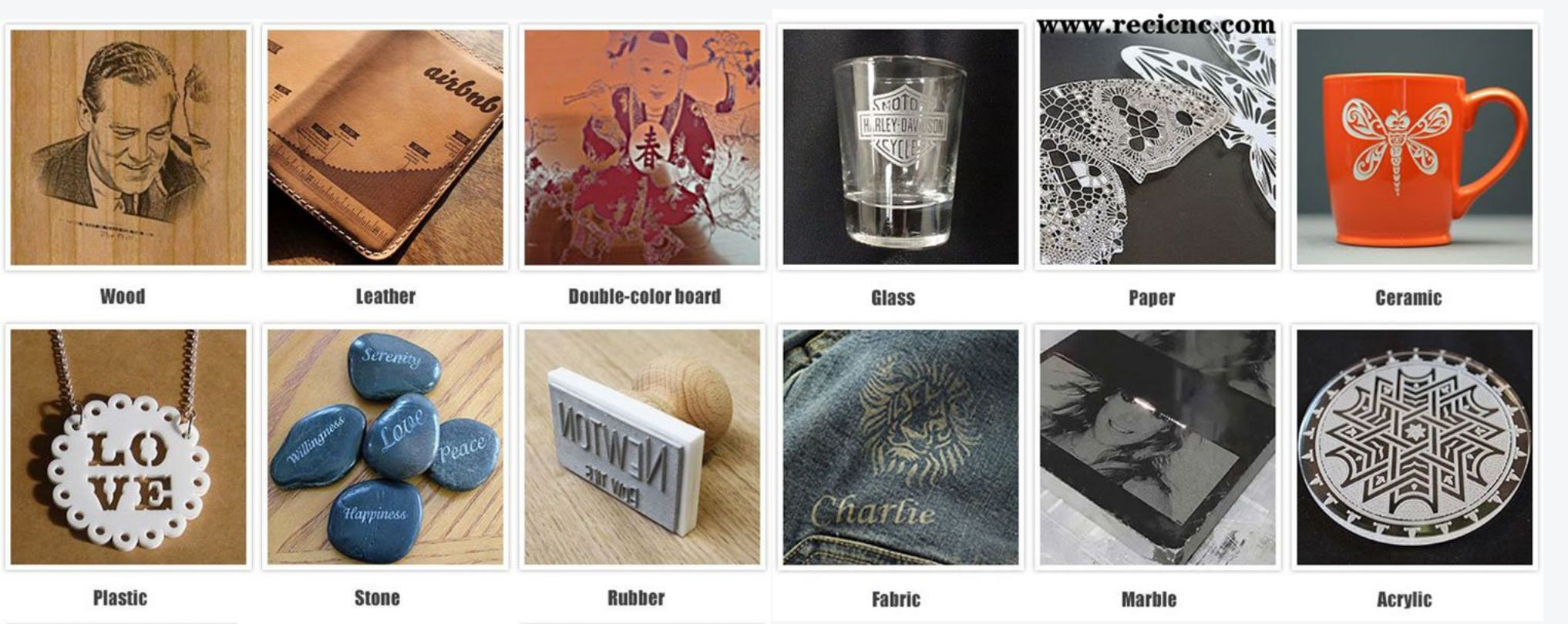

Application |

LASER CUTTING

|

Applicable Material |

Acrylic, Glass, Leather, MDF, Paper, Plastic |

|

Graphic Format Supported |

AI, BMP, Dst, DXF, PLT, Dwg, LAS, DXP |

Cutting Area |

1300mm*2500mm |

|

Key Selling Points |

Easy to Operate |

CNC or Not |

Yes |

|

Cooling Mode |

WATER COOLING |

Control Software |

Ruida |

|

Feature |

Deep marking |

Laser Power |

10W/20W/30W/50W/100W |

|

Laser Source Brand |

EFR/RECI/YONGLI/Silver |

Certification |

CE, ISO9001 |

|

Servo Motor Brand |

Leadshine |

Key Selling Points |

High-accuracy |

|

Guiderail Brand |

HIWIN |

Control System Brand |

RuiDa |

|

Applicable Industries |

Hotels, Garment Shops, Building Material Shops |

Core Components |

laser supply |

|

Mode of Operation |

Pulsed |

After Warranty Service |

Online support |

|

Optical Lens Brand |

II-VI |

Mainly function |

Metal and nonmetal cutting |

|

Video outgoing inspection |

Provided |

Graphic Format Supported |

AI, PLT, DXF, Dwg, DXP |

|

Place of Origin |

Jinan,Shandong Province |

Warranty time |

3 years |

Main Parts for Machine

Machine Video

Mixed Co2 Laser Cutting Machine for cut metal

Main Feature of laser cutting machine

1. RZ-1325 is high end laser cutting machine with European standard design and assembly, and it is popular in high end market, such as Europe, North America and China.

2. About working area : 1300*2500mm or 1500*3000mm, which could meet advertisement and wood furniture industry.

3. Blade worktable makes sure the contact surface between the cutting material and the platform is minimized, and the best cutting effect can be achieved.

4. Wide range: carbon dioxide laser can carve and cut almost any non-metallic material. And the price is low!

5. Consistent effect: ensure that the processing effect of the same batch is completely consistent.

6. Adjustment of Guide Rail: The machine use Taiwan HIWIN liner guide rail to ensure the precision of crossbeam motion.The engineer can adjust the rail direction by using the interferometer, to keep the degree of parallel, make sure the deviation under control within 0.1mm. That makes the motion of X,Y axis smoothly and accurately, improve the working accuracy.

7. Belt transmission: X,Y axis motion system adopts stepper motor-belt transmission

Cutting parameter

|

Silver laser tube cutting parameter for Acrylic |

|||||||

|

Thickness |

5mm |

10mm |

20mm |

30mm |

|||

|

TS1-220W |

31-33mm/s |

13-15mm/s |

5-7mm/s |

4-5mm/s |

|||

|

TS2-300W |

45-47mm/s |

19-21mm/s |

7-9mm/s |

6-8mm/s |

|||

|

TS3-500W |

70-80mm/s |

31-36mm/s |

13-15mm/s |

12-14mm/s |

|||

|

TS4-600W |

90-95mm/s |

40-45mm/s |

15-20mm/s |

14-16mm/s |

|||

|

Silver laser tube cutting parameter for SS,CS |

||||||

|

Material |

Thickness |

Auxiliary gas |

220W(T1) |

300W(T2) |

500W(T3) |

600W(T4) |

|

Stainless steel |

0.5 |

Oxygen |

70 |

100 |

144 |

180 |

|

1 |

Oxygen |

18 |

60 |

96 |

110 |

|

|

2 |

Oxygen |

8 |

25 |

25 |

60 |

|

|

3 |

Oxygen |

4 |

10 |

10 |

25 |

|

|

Carbon steel |

0.5 |

Oxygen |

33 |

110 |

110 |

220 |

|

1 |

Oxygen |

25 |

80 |

80 |

150 |

|

|

2 |

Oxygen |

10 |

30 |

30 |

80 |

|

|

3 |

Oxygen |

5 |

15 |

15 |

35 |

|

|

Silver laser tube cutting parameter for photo frame, plate, wood |

||||||

|

Thickness |

12mm |

20mm |

30mm |

|||

|

TS1-220W |

6-10mm/s |

3-6mm/s |

2-5mm/s |

|||

|

TS2-300W |

20-25mm/s |

10-45mm/s |

6-8mm/s |

|||

|

TS3-500W |

35-40mm/s |

17-22mm/s |

12-15mm/s |

|||

|

TS4-600W |

45-50mm/s |

23-28mm/s |

18-20mm/s |

|||

Cutting sample

Product detail pictures:

Related Product Guide:

We've numerous great employees customers excellent at promoting, QC, and working with kinds of troublesome difficulty inside the generation method for Manufacturer Of Fiber Laser Marking Machine - Metal&Nonmetal Laser Cutting Machine – Rezes , The product will supply to all over the world, such as: Austria, Poland, Philippines, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We're confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!