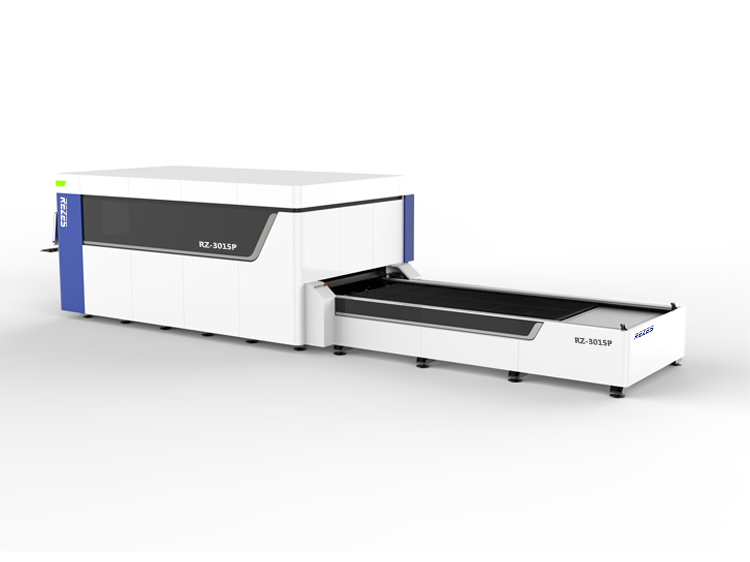

Hot Selling For Fiber Laser Cutting Machine For Jewelry - Metal Fiber Laser Cutting Machine With Exchange Platform – Rezes

Hot Selling For Fiber Laser Cutting Machine For Jewelry - Metal Fiber Laser Cutting Machine With Exchange Platform – Rezes Detail:

Product Display

Technical parameter

|

Application |

Laser Cutting |

Applicable Material |

Metal |

|

Cutting Area |

1500mm*3000mm |

Laser Type |

|

|

Control Software |

Cypcut |

Laser Head Brand |

Raytools |

|

Servo Motor Brand |

Yaskawa motor |

Machinery Test Report |

Provided |

|

Graphic Format Supported |

AI, PLT, DXF, BMP, Dst, Dwg, DXP |

CNC or Not |

Yes |

|

Key Selling Points |

High-accuracy |

Warranty of core components |

12 months |

|

Mode of Operation |

automatic |

Positioning Accuracy |

±0.05mm |

|

re-positioning accuracy |

±0.03mm |

Peak Acceleration |

1.8G |

|

Applicable Industries |

Hotels, Building Material Shops, Manufacturing Plant |

Pneumatical parts |

SMC |

|

Mode of Operation |

continuous wave |

Feature |

Double platform |

|

Cutting Speed |

depending on power and thickness |

Control Software |

Tubepro |

|

Cutting Thickness |

0-50mm |

Guiderail Brand |

HIWIN |

|

Electrical parts |

schneider |

Warranty time |

3 years |

Characteristics of laser cutting machine for metal sheet

1.Stability and reliability of light path system and control system.

2.Imported original fiber lasers,high and stable function,lifespan is over 100000 hours.

3.Higher cutting quality and efficiency ,cutting speed is up to 80m/min with appearance and beautiful cutting edge.

4.German high performance reducer,gear and rack;Japanese guide and ball screw. Applicable Industry and materials: fiber laser cutting machine application:metal cutting, electrical switch manufacturing, aerospace, food machinery, textile machinery, engineering machinery, locomotive manufacturing, agriculture and forestrymachinery, elevatormanufacture, special vehicles, household appliances, tools, processing, IT manufacturing, oil machinery, food machinery, diamond tools, welding, welding gear, metal materials, decoration advertising, laser surface treatment of foreign processing services, such as all kinds of machinery processing industry.Our fiber laser cutting machine‘s Application Materials:Professional used to cut thin sheet metal, in a variety of high quality 0.5 -3 mm carbon steel sheet cutting, can also be cutting stainless steel plate, aluminum alloy plate, galvanized sheet, electrolyticplate, silicon steel, titanium alloy, aluminium zinc plate and other metal.

Machine Video

Metal Fiber Laser Cutting Machine With Exchange Platform

Cutting samples

The main standard for fiber laser cutting machine

1. Roughness. The laser cutting section will form vertical lines, and the depth of the lines determines the roughness of the cutting surface. The shallower the lines, the smoother the cutting section. Roughness not only affects the appearance of the edge, but also the friction characteristics. In most cases, the roughness needs to be minimized, so the shallower the texture, the better the cut quality.

2. Verticality. When the thickness of the sheet metal exceeds 10mm, the verticality of the cutting edge is very important. As you move away from the focal point, the laser beam becomes divergent and the cut widens towards the top or bottom depending on the position of the focal point. The cutting edge deviates from the vertical line by a few percent of a millimeter, the more vertical the edge, the higher the cutting quality.

3. Cutting width. Generally speaking, the width of the cut does not affect the quality of the cut. It is only when a particularly precise contour is formed inside the part that the width of the cut has an important effect. This is because the width of the cut determines the minimum inner diameter of the contour. of increase. Therefore, in order to ensure the same high precision, the workpiece should be constant in the processing area of the laser cutting machine regardless of the width of the incision.

4. Texture. When cutting thick plates at high speed, the molten metal does not appear in the incision under the vertical laser beam, but sprays out at the back of the laser beam. As a result, curved lines are formed at the cutting edge, and the lines closely follow the moving laser beam. To correct this problem, reducing the feed rate at the end of the cutting process can greatly eliminate the formation of lines.

5. Glitch. The formation of burrs is a very important factor that determines the quality of laser cutting. Because the removal of burrs requires additional workload, the severity and amount of burrs can intuitively judge the quality of cutting.

Product detail pictures:

Related Product Guide:

We take customer-friendly, quality-oriented, integrative, innovative as objectives. Truth and honesty is our management ideal for Hot Selling For Fiber Laser Cutting Machine For Jewelry - Metal Fiber Laser Cutting Machine With Exchange Platform – Rezes , The product will supply to all over the world, such as: Sri Lanka, Karachi, UK, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!