High Quality Laser Cutting Machines - Metal Tube & Pipe Laser Cutting Machine – Rezes

High Quality Laser Cutting Machines - Metal Tube & Pipe Laser Cutting Machine – Rezes Detail:

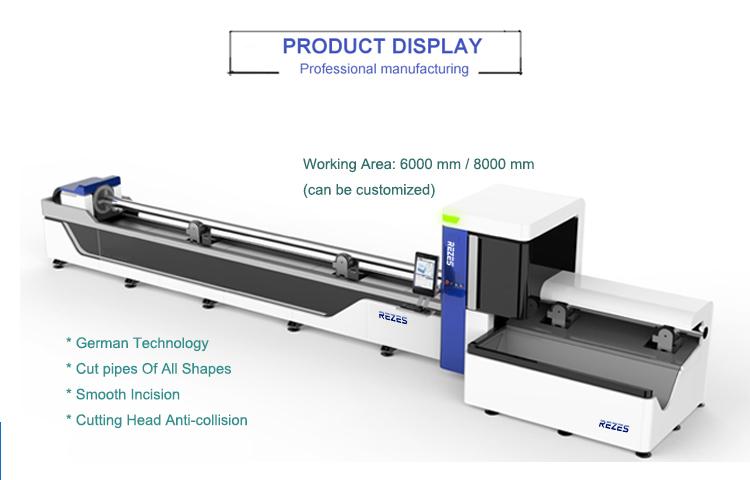

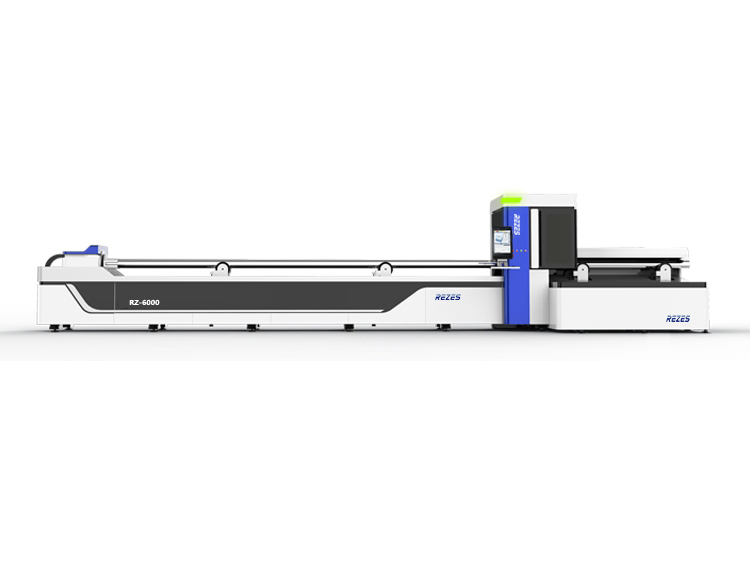

Product Display

Technical parameter

|

Application |

Laser Cutting |

Applicable Material |

Metal |

|

Condition |

New |

Laser Type |

|

|

Control Software |

Cypcut |

Laser Head Brand |

Raytools |

|

Penumatic chuck |

20-350mm |

Cutting Length |

3m/6m |

|

Servo Motor Brand |

Yaskawa motor |

Laser source |

IPG Raycus MAX JPT |

|

Graphic Format Supported |

AI, PLT, DXF, BMP, Dst, Dwg, DXP |

CNC or Not |

Yes |

|

Key Selling Points |

High Safety Level |

Warranty of core components |

12 months |

|

Mode of Operation |

automatic |

Positioning Accuracy |

±0.05mm |

|

re-positioning accuracy |

±0.03mm |

Peak Acceleration |

1.8G |

|

Applicable Industries |

Hotels, Building Material Shops, Manufacturing Plant |

Pneumatical parts |

SMC |

|

Mode of Operation |

continuous wave |

Feature |

Double platform |

|

Cutting Speed |

depending on power and thickness |

Control Software |

Tubepro |

|

Core Components |

Laser Generator |

Guiderail Brand |

HIWIN |

|

Electrical parts |

schneider |

Warranty time |

3 years |

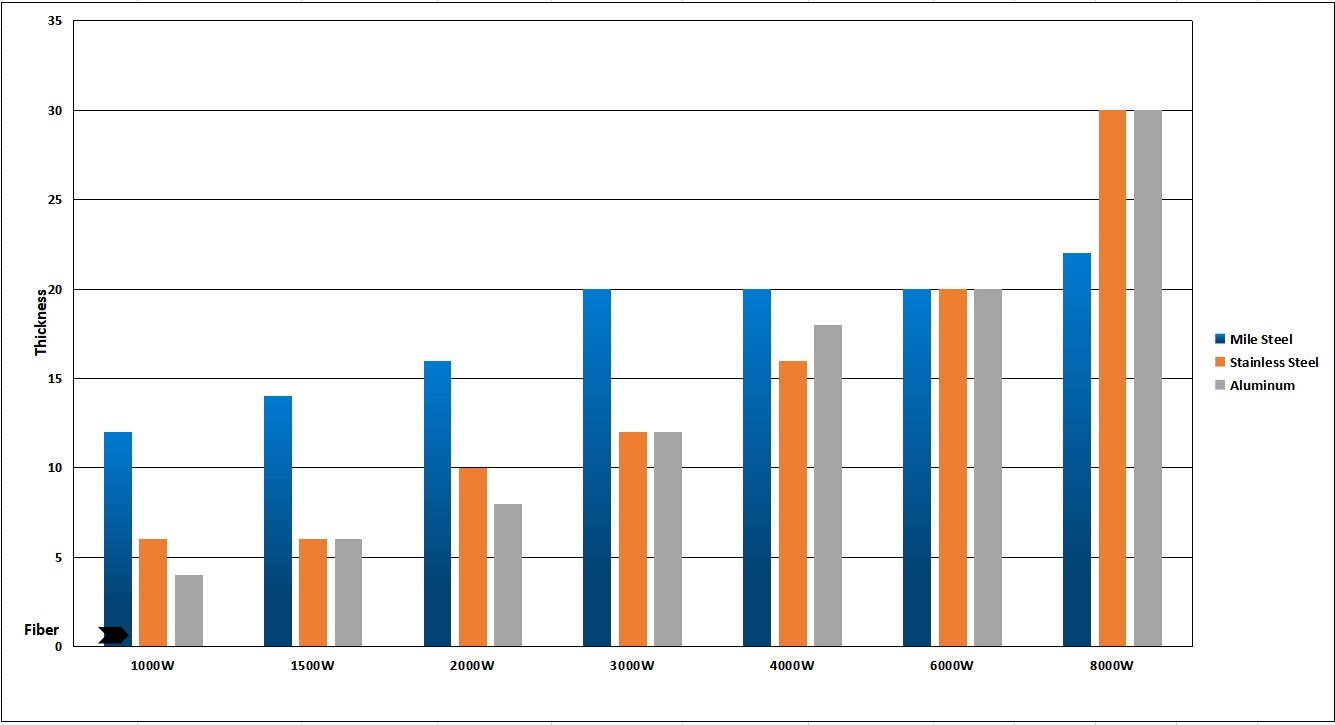

Cutting ability

The machine video

Automatic Loading and Unloading Metal Square and Round Tube Fiber Laser Pipe Cutting Machine

Main advantage of machine

1. Using Raycus laser source, the electro-optical conversion efficiency is high, which can save power consumption during work and save operating cost.

2. The focal length of the cutting head can be self-adjusted following the surface height of the material, even if the surface of the material is not flat, the cutting quality can be guaranteed.

3. Equipped with a handheld controller, you can manually control the cutting position.

4. With precision ball screw, rack and pinion, linear guide transmission operation, thus achieving high precision, high efficiency and stability of the machine tool.

5. The switch of the solenoid valve and the proportional valve is controlled by the system. The input value in the numerical control system can control the size of the proportional valve outlet, without manual adjustment

6. High-strength integrated welding fuselage and aerospace-grade aluminum alloy beams are subjected to high-temperature annealing to ensure long-term use without deformation.

Workshop & Packing

1. Anti-collision package edge: All parts of the machine are covered with some soft materials, mainly the use of pearl wool.

2. Fumigation wooden box: Our wooden box is fumigated, do not need to check the wood, saving the transport time.

3. Whole film packaging machine: Avoid all damage that may occur during delivery. Then we will cover the plastic package tightly to ensure that the soft material is covered intact, also avoiding water and rust.

The outermost is a wooden box with a fixed template.

4.Wooden box at the bottom of a solid iron socket for easy handling.

Cutting sample

Product detail pictures:

Related Product Guide:

To be able to give you benefit and enlarge our business, we also have inspectors in QC Team and assure you our greatest service and products for High Quality Laser Cutting Machines - Metal Tube & Pipe Laser Cutting Machine – Rezes , The product will supply to all over the world, such as: Mauritius, European, New Delhi, The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer's trust and support! In the future, we are going to continue with the most qualified and high quality service to offer the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

The company keeps to the operation concept scientific management, high quality and efficiency primacy, customer supreme, we have always maintained business cooperation. Work with you,we feel easy!