Good Wholesale Vendors CNC Co2 Laser Engraver And Cutter - Mini Portable Laser Machine for cutting, welding and clean – Rezes

Good Wholesale Vendors CNC Co2 Laser Engraver And Cutter - Mini Portable Laser Machine for cutting, welding and clean – Rezes Detail:

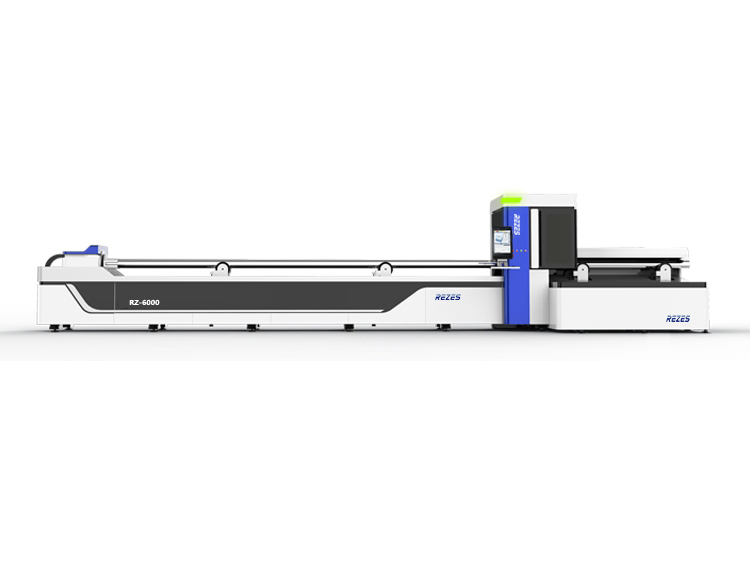

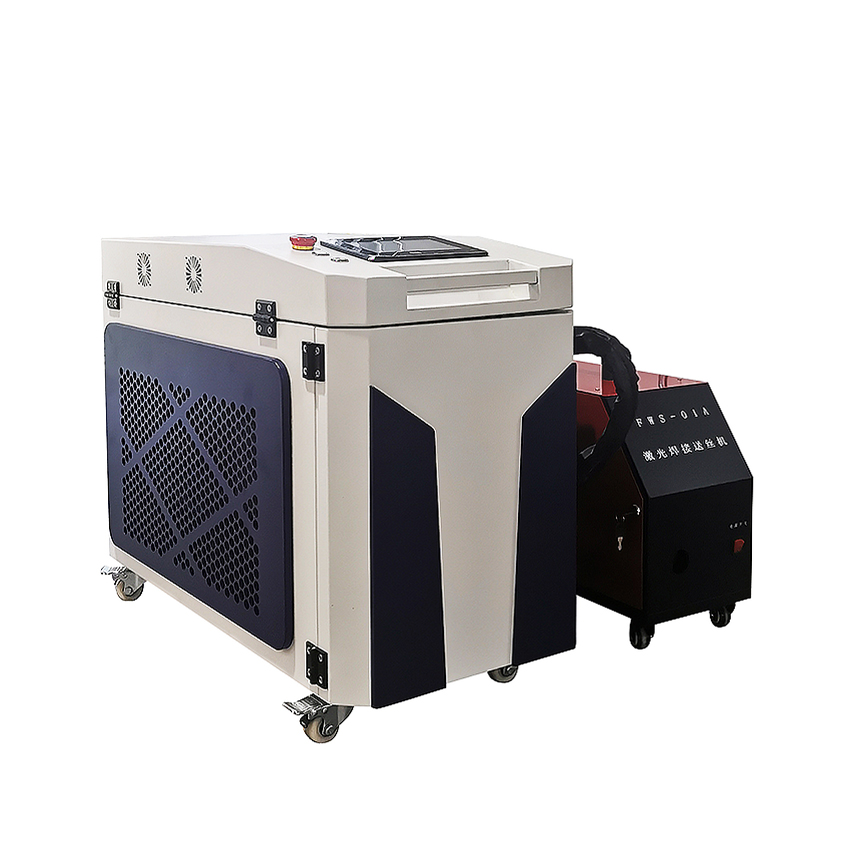

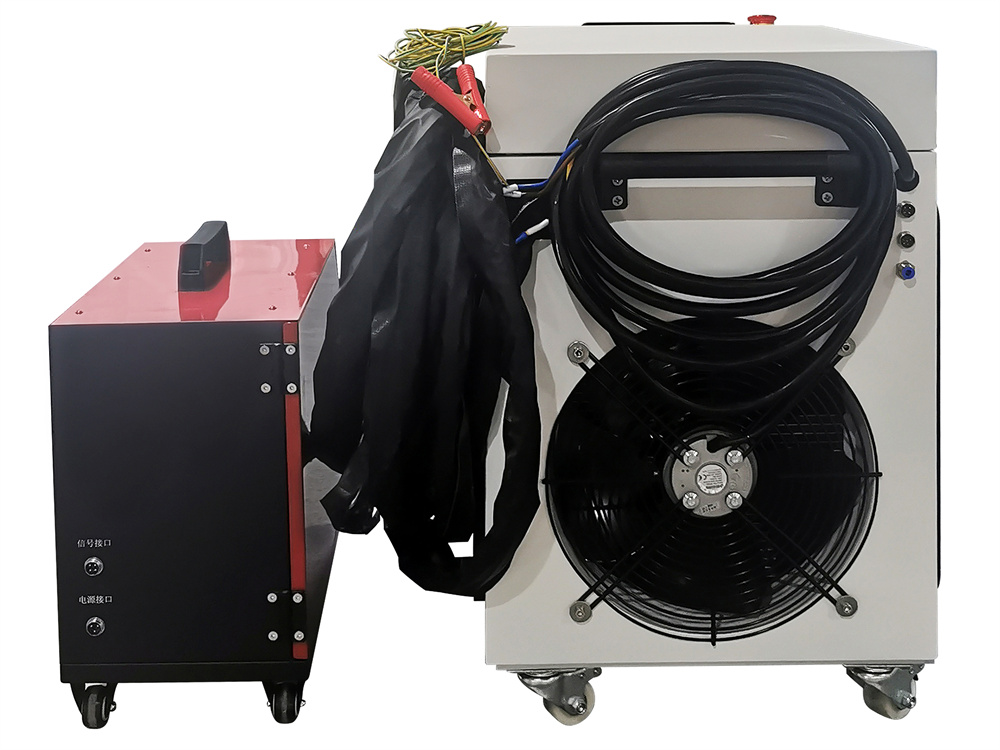

Product Display

Technical parameter

|

Condition |

New |

Core Components |

Laser Source |

|

Usage |

Weld Metal |

Max. Output Power |

2000W |

|

Applicable Material |

Metal |

Cnc Or Not |

Yes |

|

Cooling Mode |

Water Cooling |

Control Software |

Ruida/Qilin |

|

Pulse Width |

50-30000Hz |

Laser Power |

1000w/ 1500w/ 2000w |

|

Weight (Kg) |

300 Kg |

Certification |

Ce, Iso9001 |

|

Core Components |

Fiber Laser Source, Fiber, Handle Laser Welding Head |

Key Selling Points |

High-Accuracy |

|

Function |

Metal Part Laser Welding |

Fiber Length |

≥10m |

|

Applicable Industries |

Hotels, Garment Shops, Building Material Shops |

Core Components |

Laser Supply |

|

Mode Of Operation |

Pulsed |

After Warranty Service |

Online Support |

|

Focal Spot Diameter |

50μm |

Wavelength |

1080 ±3nm |

|

Video Outgoing Inspection |

Provided |

Graphic Format Supported |

Ai, Plt, Dxf, Dwg, Dxp |

|

Place Of Origin |

Jinan,Shandong Province |

Warranty Time |

3 Years |

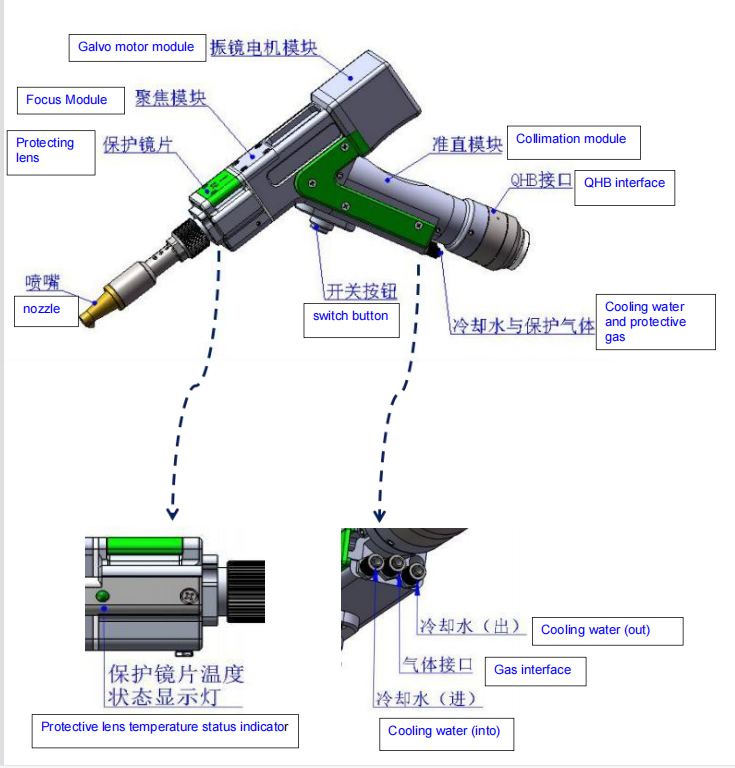

Main Parts for Machine

Main function of machine

The three-in-one laser welding and cleaning machine can cut, weld and clean metals without purchasing multiple laser equipment separately. It is suitable for welding stainless steel and aluminum alloys, and can also weld carbon steel, titanium alloys, etc., and can also be used for welding. Rust removal and hand-held metal cutting. For cleaning of metal rust, paint, oil and coatings, saving cost and space.

It can weld a variety of metal plates and pipes, mainly suitable for welding stainless steel, gold, silver, copper, galvanized sheet, aluminum sheet, various alloy sheets, rare metals and other materials.

Copper alloy surface patina cleaning, steel pipe surface oxide and pollutant cleaning, rail derusting.

Widely used in advertising signs, hardware products, auto parts, craft gifts and other industries, can be used for welding carbon steel, stainless steel, titanium, aluminum and other metal materials.

About usage of machine

1.Product Structure

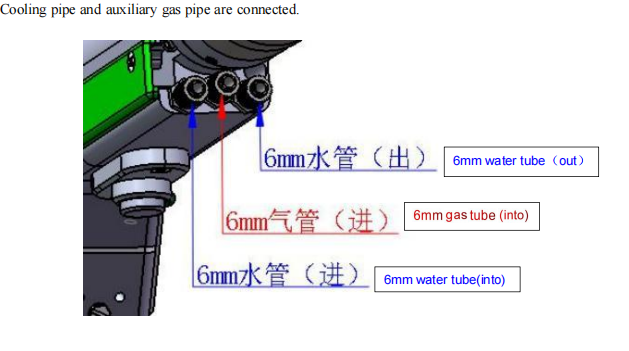

2.Pipe connection

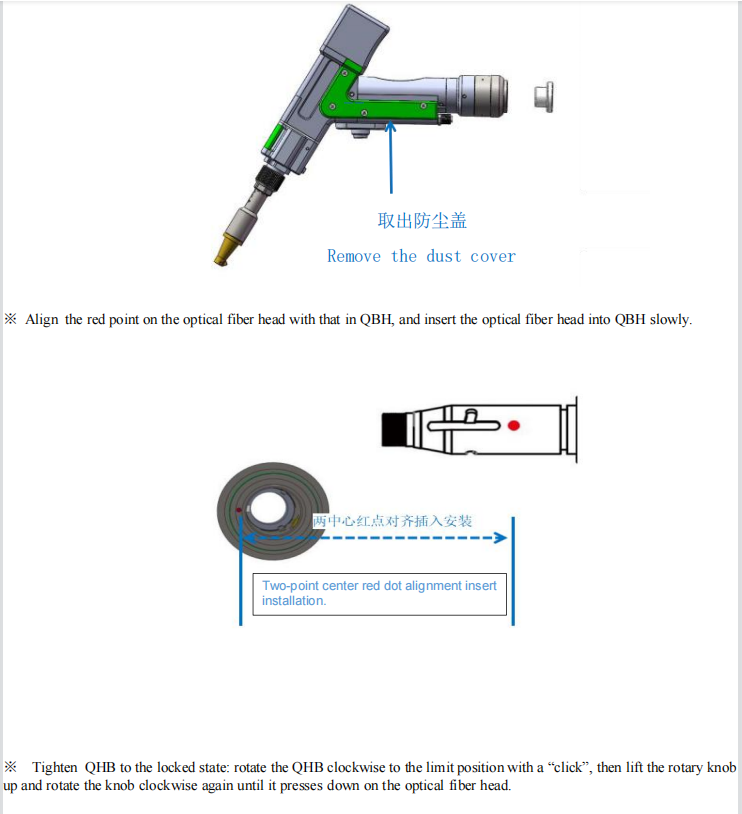

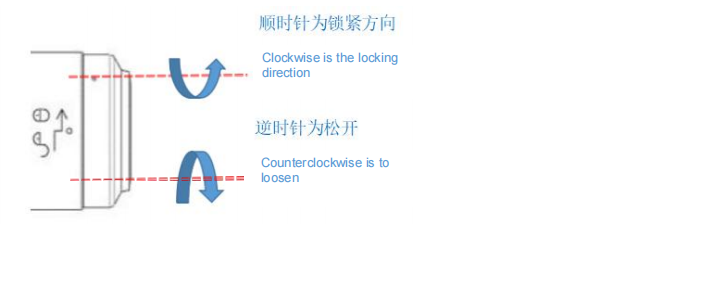

3.Fiber input installation

Maintenance of Laser head

- Fiber laser lens :

Operating method and cautions: Tool: dust-free gloves or dust-free fingertips, dust-free cotton swab, isopropy alcohol and canned dry pure compressed air. Spray the isopropyl alcohol onto the dust-free cotton swab, make the lens face your eyes, gently pinch the side edge ofthe lens with the thumb and forefinger of your left hand, wipe the front and back ofthe lens in one direction from left to right or from top to bottom with dust-free cotton swab held in the right hand ( remember not to wipe the lens back and forth to avoid the second contamination), and blow the surface of the lens with dry pure compressed air to ensure there is no dust on the lens.

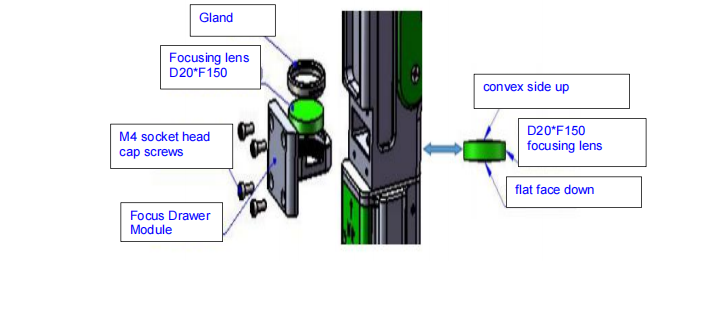

Disassembly of focusing lens:

Tool: 2mm inner hexagon wrench, clean cotton swab, alcohol and masking tape The assembly and disassembly of lens should be operated with hands wearing dust-free gloves or fingertips in clean environment.

Steps Step 1: loosen M4 screw with a 2mm inner hexagon wrench. Step 2: pull out ofthe focusing module horizontally Step 3: seal the port with masking tape to stop dust from entering the cavity to cause contamination. Step 4: the cover is gently pressed down and rotated 90°.Align the two convex places with the left and right openings. Take out the cover upward and the protective lens can be changed. (Note: install lens in concave and convex direction.)

Product detail pictures:

Related Product Guide:

Persisting in High quality, Prompt Delivery, Aggressive Price, now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for Good Wholesale Vendors CNC Co2 Laser Engraver And Cutter - Mini Portable Laser Machine for cutting, welding and clean – Rezes , The product will supply to all over the world, such as: Czech Republic, Italy, Durban, We have top engineers in these industries and an efficient team in the research. What is more, now we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Remember to find our website to check more information from our merchandise.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.