Glass tube CO2 Laser Marking Machine

Product Display

Technical parameter

|

Application |

Laser Engraving |

Working Temperature |

15°C-45°C |

|

Laser Source Brand |

Reci/ Efr/ Yongli |

Marking Area |

300*300mm/600mm*600mm |

|

Control System Brand |

Bjjcz |

Key Selling Points |

Competitive Price |

|

Voltage |

110V/220V, 50Hz/60Hz |

Marking Depth |

0.01-1.0mm(Subjejct To Material) |

|

Graphic Format Supported |

Ai, Plt, Dxf, Bmp, Dst, Dwg, Dxp |

Laser Power |

80w/100w/150w/180w |

|

Working Accuracy |

0.01mm |

Certification |

Ce, Iso9001 |

|

Video Outgoing-Inspection |

Provided |

Mode Of Operation |

Continuous Wave |

|

Linear Speed |

≤7000mm/s |

Cooling System |

Water Cooling |

|

Control System |

Jcz |

Software |

Ezcad Software |

|

Mode Of Operation |

Pulsed |

Feature |

Low Maintenance |

|

Applicable Industries |

Building Material Shops, Manufacturing Plant |

Positioning Method |

Double Red Light Positioning |

|

Key Selling Points |

Easy To Operate |

Graphic Format Supported |

Ai, Plt, Dxf, Dwg, Dxp |

|

Place Of Origin |

Jinan,Shandong Province |

Warranty Time |

3 Years |

The difference between glass tube and RF tube

The air-cooling method used by the RF tube can be used stably for a long time without failure. The glass tube is water-cooled. If the continuous processing time of the equipment is too long or the water temperature is not within a constant range, there may be no light or unstable light output. Continuous operation will affect the quality of the product. bigger.

2. Differences in stability

The co2 radio frequency tube is relatively stable. The radio frequency tube is a fully sealed metal tube and uses a 30-volt bottom voltage power supply, which directly avoids some hidden dangers caused by the use of high-voltage power supplies. Glass tube-laser cutting machines are generally used It is a high-voltage power supply of more than 1000 volts. In addition to being unstable, there are certain dangers. Working for a long time makes the power supply easy to age, and has great interference to the control system. affect its normal function.

3. different spots

The light spot of the co2 radio frequency tube is 0.07mm, the light spot is fine, the precision is high, and the thermal diffusion area is small, which can be finely processed. The light spot of the glass tube is 0.25mm, which is more than three times that of the radio frequency tube. The light spot is relatively thick and the accuracy is relatively poor. , The light output is unstable, the heat diffusion area is large, the cutting edge is melted, and the blackening is obvious.

4. Service life

The service life of the laser of the radio frequency tube can reach more than 50,000 hours, and there is no problem in the general use of about 6 years, while the general use of the glass tube is 2,500 hours, and the glass tube needs to be replaced every six months or so.

From the above comparison, it can be seen that the RF tube is superior to the glass tube in all aspects. If the product requires low precision, the glass tube is completely sufficient.

Machine Video

Glass tube Co2 laser marking machine with 300*300 working area

The advantage and disadvantage of Co2 laser Marking Machine

Compared with traditional marking technology, the advantages of co2 laser marking machine are that the laser marking is clear, permanent, fast, high-yield, and pollution-free; graphics, text and serial numbers can be edited by software, easy to change, and laser 30,000 hours Maintenance-free, no consumables, low cost of use, energy saving, environmental protection label, in line with ROHS standards.

- Disadvantages of carbon dioxide laser marking machine:

The laser of the carbon dioxide laser marking machine is a gas laser with a wavelength of 1064um in the infrared band. It uses RF laser and high-speed galvanometer, so the price of Co2 laser marking machine is higher than that of semiconductor.

Carbon dioxide laser marking machines have certain limitations. It cannot mark products made of metallic materials. It is mainly used to mark wood, acrylic, leather and other non-metallic materials.

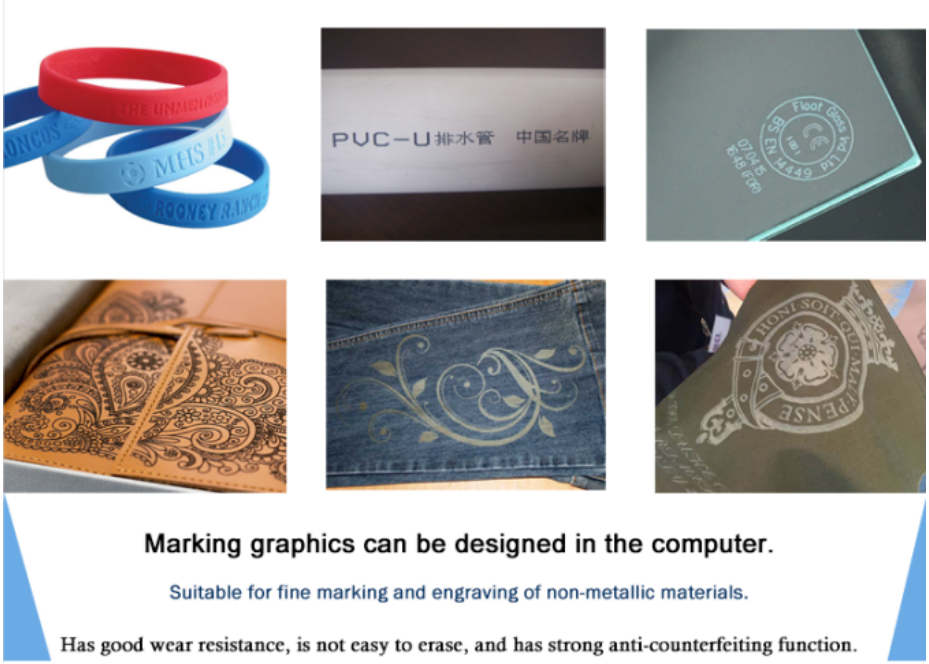

Marking sample