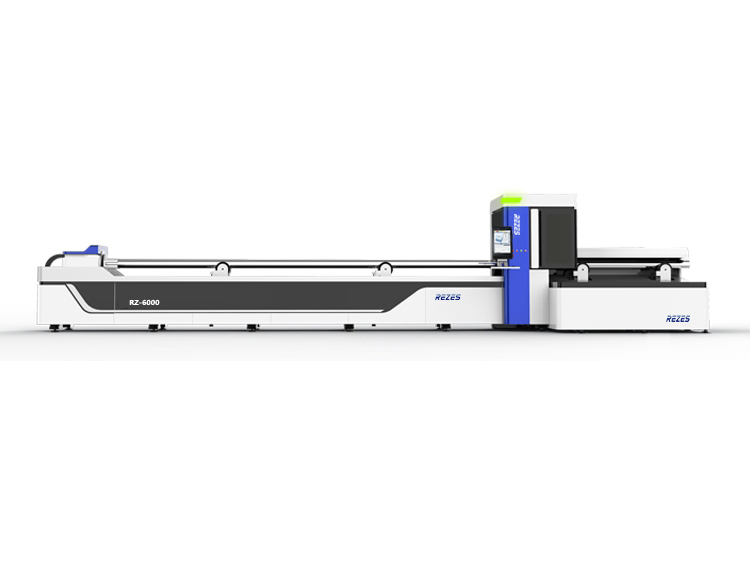

Factory Wholesale Metal Laser Cutter - Metal Sheet Fiber Laser Cutting Machine – Rezes

Factory Wholesale Metal Laser Cutter - Metal Sheet Fiber Laser Cutting Machine – Rezes Detail:

Product Display

Technical parameter

| Application | Laser Cutting | Applicable Material | Metal |

| Cutting Area | 1500mm*3000mm | Laser Type | Fiber Laser |

| Control Software | Cypcut | Laser Head Brand | Raytools |

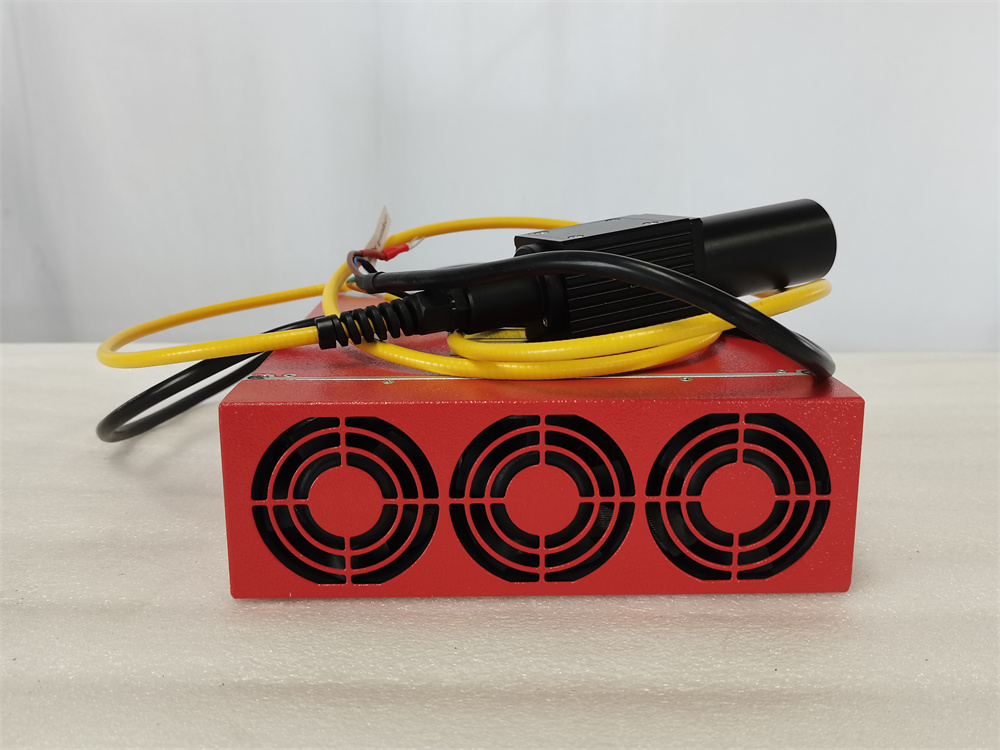

| Servo Motor Brand | Yaskawa motor | Laser Source Brand | IPG/MAX |

| Graphic Format Supported | AI, PLT, DXF, BMP, Dst, Dwg, DXP | CNC or Not | Yes |

| Key Selling Points | High-accuracy | Weight | 4500kg |

| Mode of Operation | automatic | Positioning Accuracy | ±0.05mm |

| re-positioning accuracy | ±0.03mm | Peak Acceleration | 1.8G |

| Applicable Industries | Hotels, Building Material Shops, Manufacturing Plant | Pneumatical parts | SMC |

| Mode of Operation | continuous wave | Feature | Full cover |

| Cutting Speed | depending on power and thickness | Control Software | Tubepro |

| Cutting Thickness | 0-50mm | Guiderail Brand | HIWIN |

| Electrical parts | schneider | Warranty time | 3 years |

| Configuration | 5-axis | Laser wavelength | 1080±5nm |

| Machinery Test Report | Provided | Cutting Speed | 140m/min |

| Electrical requirement | 3 Phases 380V±10% 50HZ/60HZ | Key Selling Points | Competitive Price |

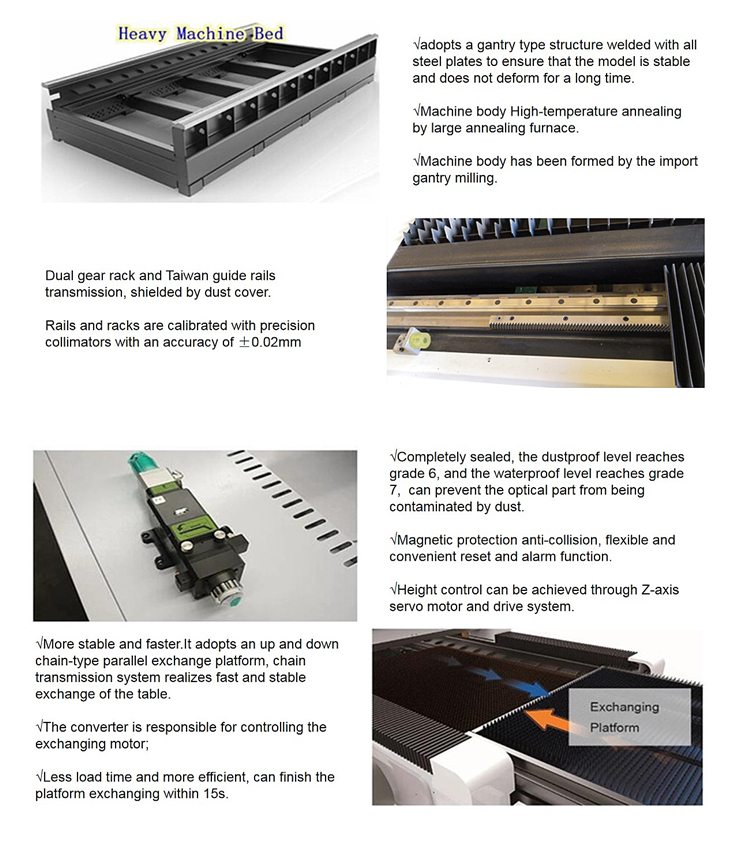

Machine Detail

Machine Video

1KW fiber laser cutting machine cutting stailless steel with high efficiency

Main advantage of machine

1. Low cost of use

One of the biggest benefits of using a fiber laser cutting machine is the low cost of use and low maintenance, which is very beneficial for companies that already have multiple machines. Spend less time on maintenance and more time on cutting products. In terms of cost of use, since the cutting efficiency is significantly ahead of other processes, the relative cost will be much lower, which is more conducive to the development of small and medium-sized enterprises.

2. High efficiency and precision

Another great benefit of choosing a fiber laser cutting machine is its high efficiency. In many areas of the cutting process, laser cutters are the most efficient on the modern market – higher photoelectric conversion efficiency, more efficient beam delivery, resulting in better finished products and less energy waste.

The cutting accuracy is unmatched by other processes. When the power is stable and the parameters are suitable, there is no need for secondary processing and grinding, and the finished product can be directly finished, which is very cost-effective.

3. Easy to operate

The new generation of fiber laser cutting machines are all computer numerical control and remote operation. After importing the cutting drawings, the work will be performed automatically. Basically, all actions can be completed with one or two keys. It is very simple and reduces labor costs. There is automatic loading and unloading, which is more convenient.

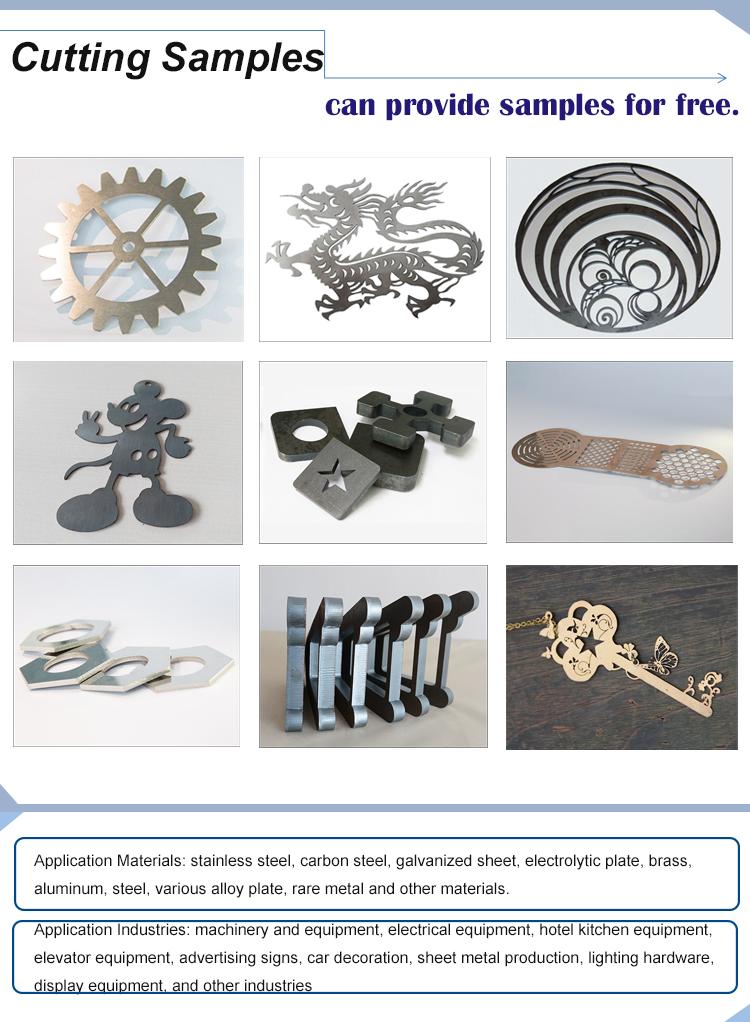

4. Wide range of use

There is a misconception that the capabilities and applications of fiber laser cutting machines are limited to heavy-duty manufacturing, however this is not the case. There are many industries and industries that can use laser cutting machines, ranging from heavy equipment, rail transit, aerospace, small to jewelry processing, advertising board processing, and the power range is large, ranging from 1000W to 30000W, the thickest Can cut 130mm sheet.

Cutting samples

Product detail pictures:

Related Product Guide:

Persisting in High high quality, Prompt Delivery, Aggressive Price, we've established long-term cooperation with clients from the two overseas and domestically and get new and old clients' superior comments for Factory Wholesale Metal Laser Cutter - Metal Sheet Fiber Laser Cutting Machine – Rezes , The product will supply to all over the world, such as: Islamabad, European, Wellington, We offer OEM services and replacement parts to meet the varying needs of our customers. We offer competitive price for quality products and we will make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

This company has the idea of better quality, lower processing costs, prices are more reasonable, so they have competitive product quality and price, that's the main reason we chose to cooperate.