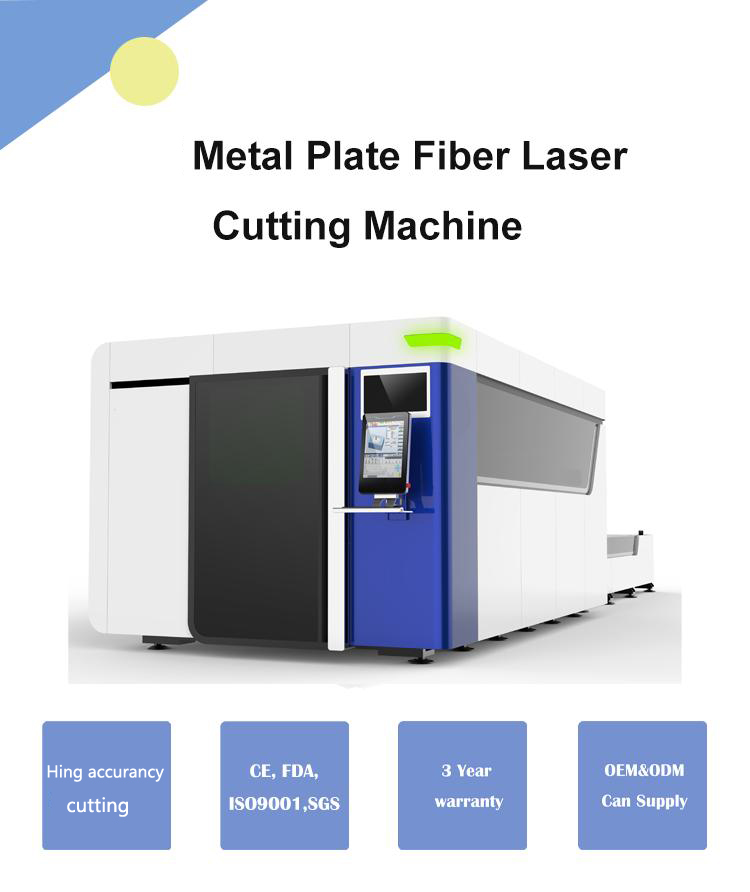

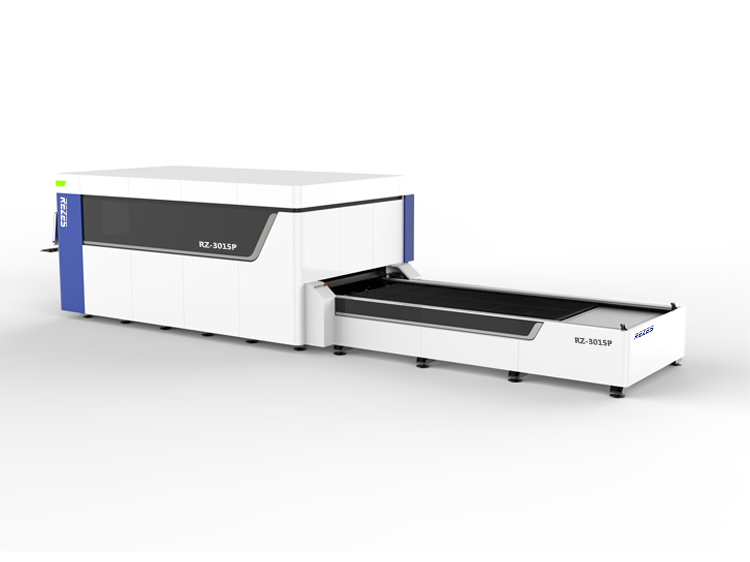

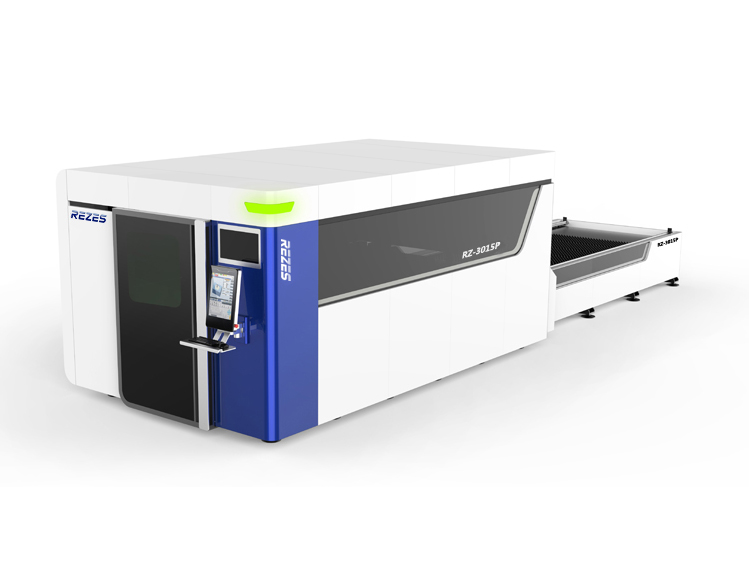

China OEM Laser Metal Cut Machine Price - Whole Cover Laser Cutting Machine – Rezes

China OEM Laser Metal Cut Machine Price - Whole Cover Laser Cutting Machine – Rezes Detail:

Product Display

Technical parameter

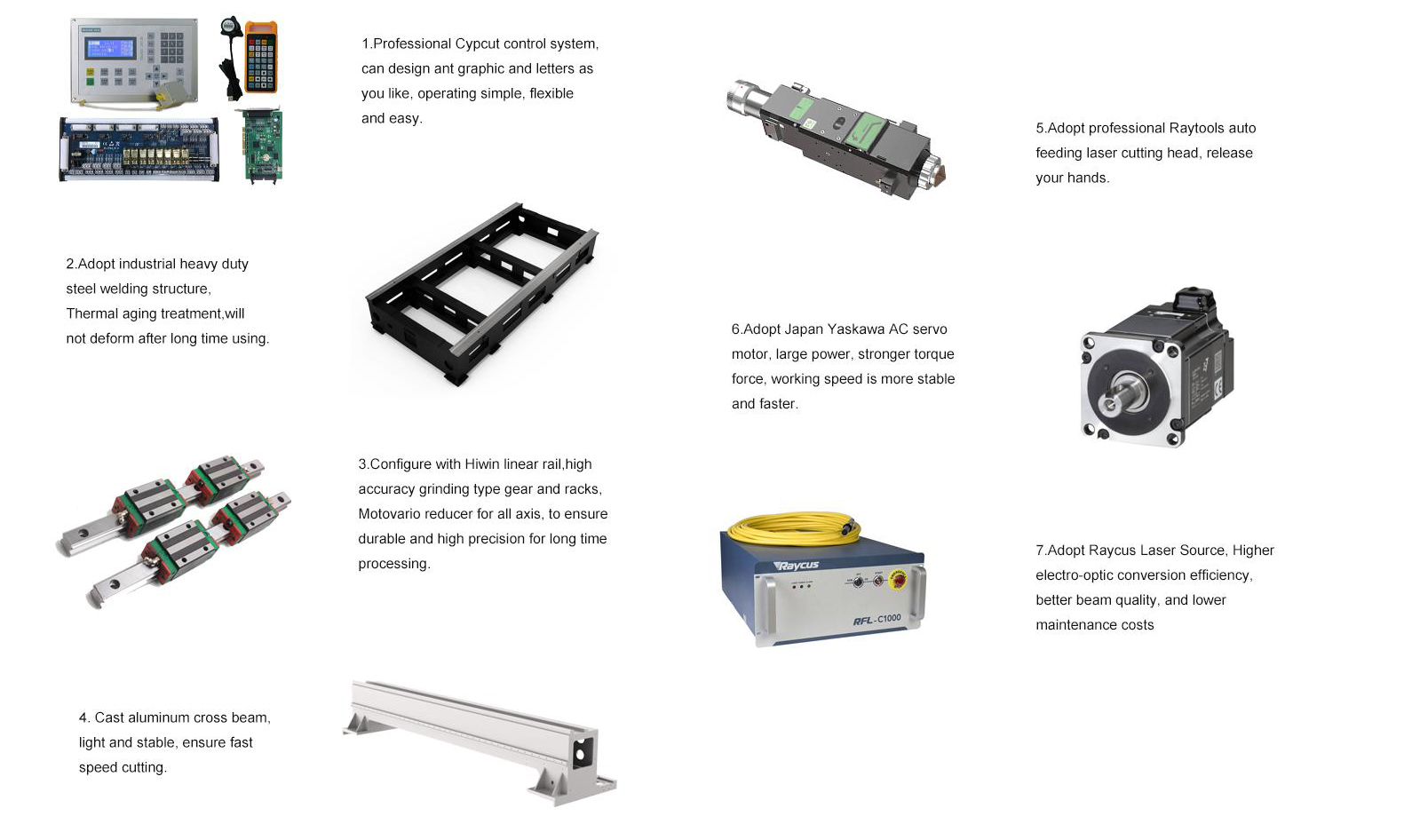

| Application | Laser Cutting | Applicable Material | Metal |

| Cutting Area | 1500mm*3000mm | Laser Type | Fiber Laser |

| Control Software | Cypcut | Laser Head Brand | Raytools |

| Servo Motor Brand | Yaskawa motor | Machinery Test Report | Provided |

| Graphic Format Supported | AI, PLT, DXF, BMP, Dst, Dwg, DXP | CNC or Not | Yes |

| Key Selling Points | High-accuracy | Weight | 4500kg |

| Mode of Operation | automatic | Positioning Accuracy | ±0.05mm |

| re-positioning accuracy | ±0.03mm | Peak Acceleration | 1.8G |

| Applicable Industries | Hotels, Building Material Shops, Manufacturing Plant | Pneumatical parts | SMC |

| Mode of Operation | continuous wave | Feature | Full cover |

| Cutting Speed | depending on power and thickness | Control Software | Tubepro |

| Cutting Thickness | 0-50mm | Guiderail Brand | HIWIN |

| Electrical parts | schneider | Warranty time | 3 years |

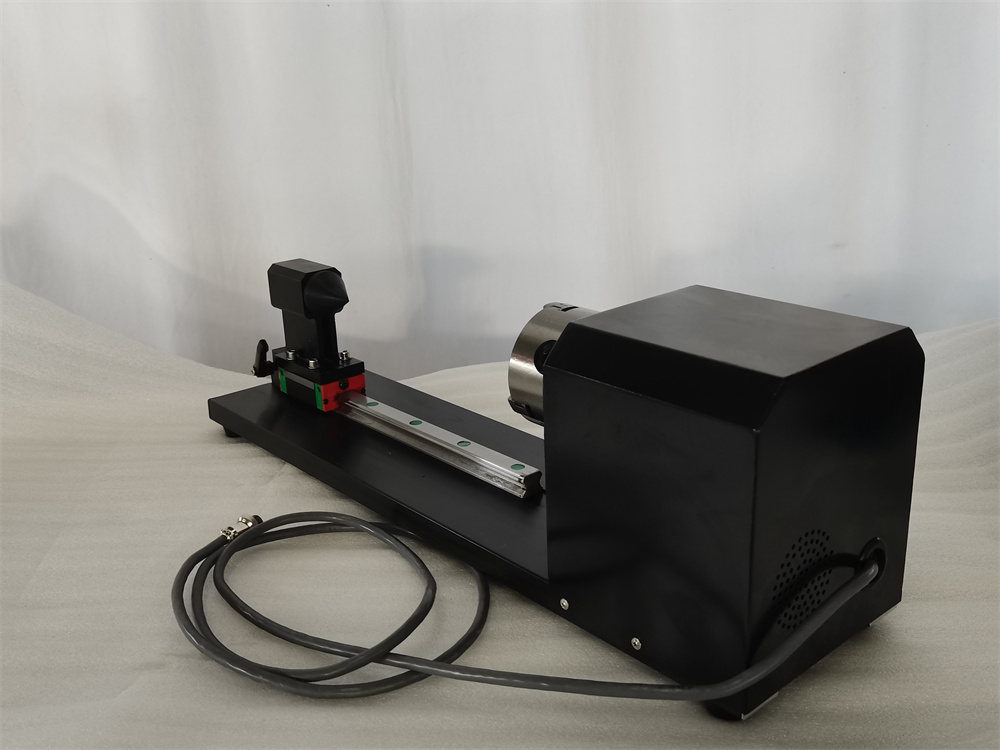

Machine parts

Machine Video

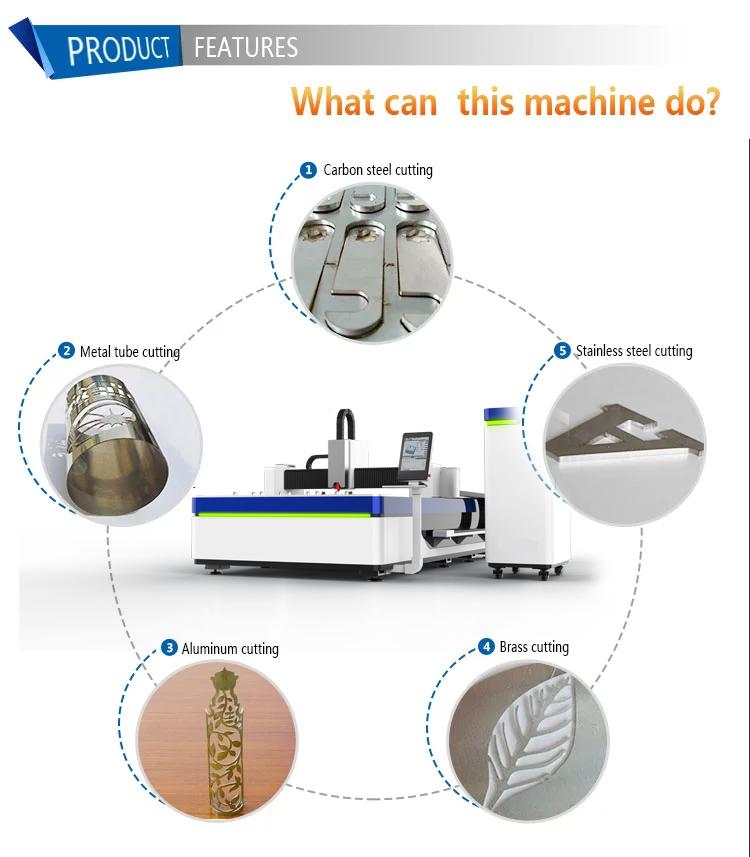

Whole Cover Laser Cutting Machine

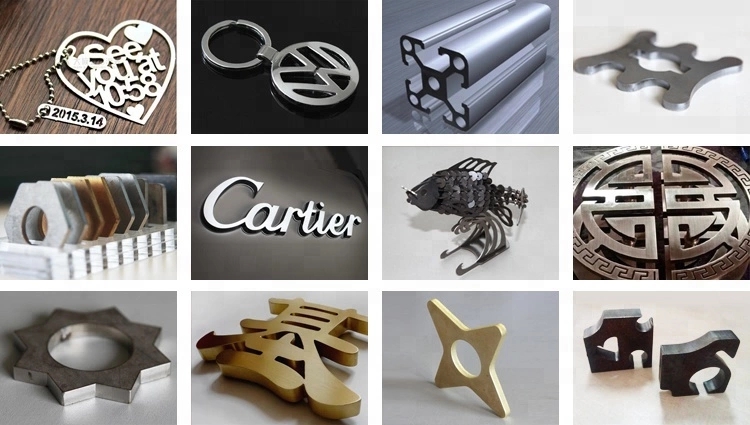

Cutting samples

Application

1. Automotive industry

Laser cutting machines are used in car front covers, car sheet metal, car exhaust pipes, etc., and need to be processed after forming some excess corners or burrs. If manual operation is used, it is difficult to achieve the desired standard of efficiency and precision.

2. Decoration industry

The decoration industry needs to use a lot of complex graphics, and the laser cutting machine can meet the application of this industry with its fast cutting speed and flexible cutting, and is very popular among decoration companies. After designing the relevant drawings, one-click import can be cut out.

3.Advertising industry

Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters,LED Letters.

4.Household appliances and kitchenware industry

Home appliances and kitchen utensils are basically made of thin plates. Before the stamping and drawing process, the fiber laser cutting machine is used to process the samples to quickly develop new products. The cutting speed of the laser processing equipment is fast, which greatly improves the processing efficiency. At the same time, the laser processing equipment has high cutting precision, which improves the yield of range hoods and burning appliances. For some special-shaped products, fiber laser cutting machines have unique advantages, including power distribution cabinets, filing cabinets, etc., all of which are standardized production of thin plates and require efficiency. The use of laser cutting machines can significantly improve efficiency.

5.Agricultural machinery industry

There are many types of sheet metal processing parts for agricultural machinery products, and they are updated quickly. The traditional sheet metal processing parts of agricultural machinery products usually use the punching method, which consumes a lot of molds. If the processing of parts still stays in the traditional way, it will seriously restrict the replacement of products. The flexible processing characteristics of the laser are reflected. Laser processing can realize the cutting of various shapes of plates with the help of programming software. Using laser processing not only has fast processing speed, high efficiency, and low cost, but also does not need to replace molds or tools, shortening the production preparation time. It can also keep up with the pace when the product is updated, and the new style can be cut by re-drawing and programming. It is easy to realize continuous processing, the laser beam transposition time is short, and the production efficiency is high. Various workpieces can be installed alternately. When a workpiece is processed, the completed parts can be removed and the workpiece to be processed can be installed to realize parallel processing.

6.Construction machinery industry

In the construction machinery industry, fiber laser cutting circular holes can be used as long as the diameter of the workpiece circular hole is greater than or equal to the plate thickness, and the roughness and diameter requirements are within the guaranteed capacity of the cutting machine when faced with a specific plate thickness. The laser directly cuts the material, eliminating the drilling process and improving the labor production efficiency. For some workpieces with many holes, the spotting function of the fiber laser cutting machine is used to determine the position of the hole, which saves the time for positioning the hole for the subsequent hole drilling process, and also saves the production cost of the drilling template, which not only improves the production efficiency, but also improve the accuracy of the product.

Product detail pictures:

Related Product Guide:

We will constantly satisfy our respected customers with our good excellent, superior value and superior assistance due to we're additional experienced and far more hard-working and do it in cost-effective way for China OEM Laser Metal Cut Machine Price - Whole Cover Laser Cutting Machine – Rezes , The product will supply to all over the world, such as: America, Canada, Oman, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information and we will offer you competitive price list then.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.