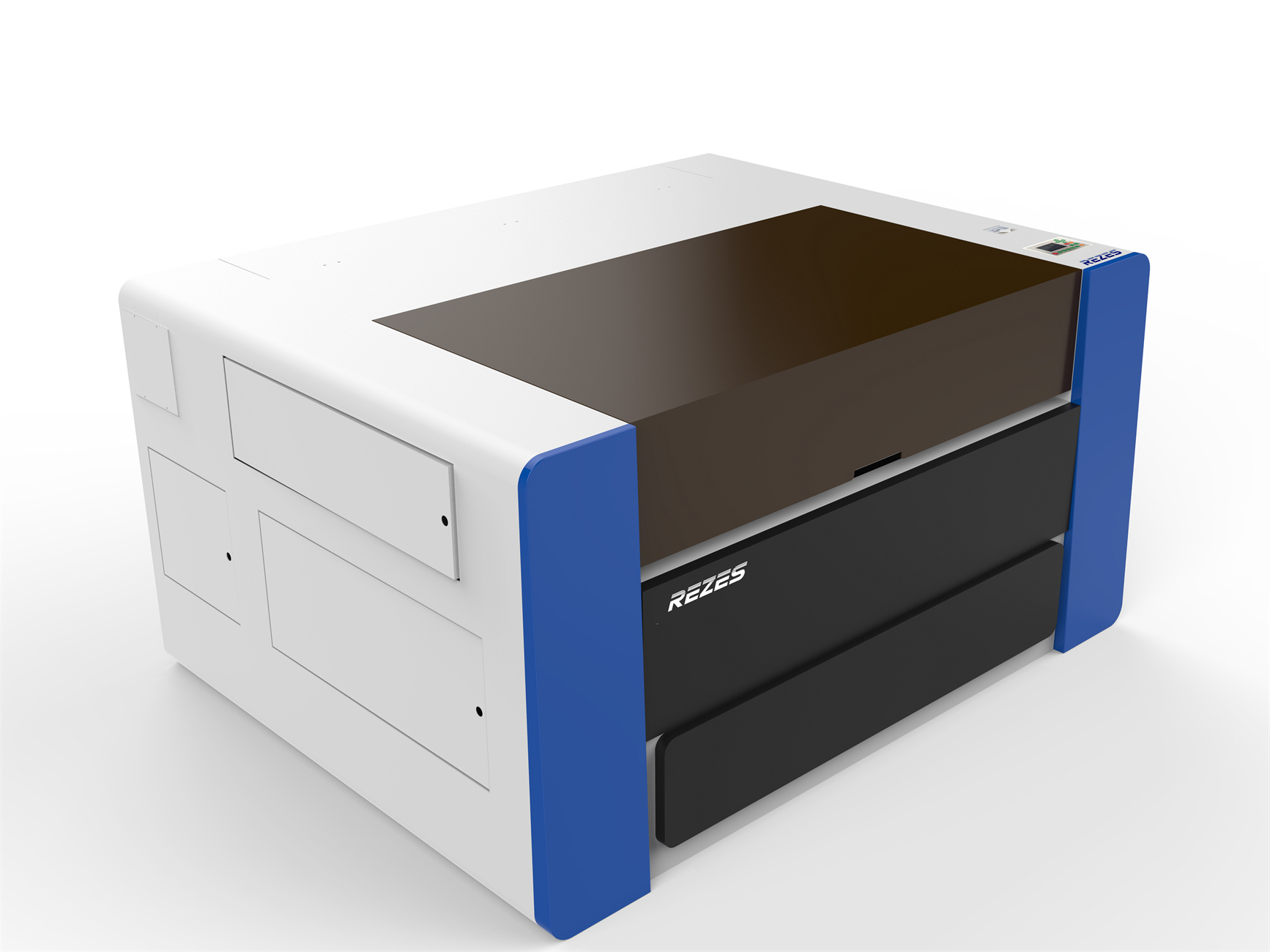

Best Price On Laser Printing Machine - Handheld Laser Welding Machine – Rezes

Best Price On Laser Printing Machine - Handheld Laser Welding Machine – Rezes Detail:

Short description content section

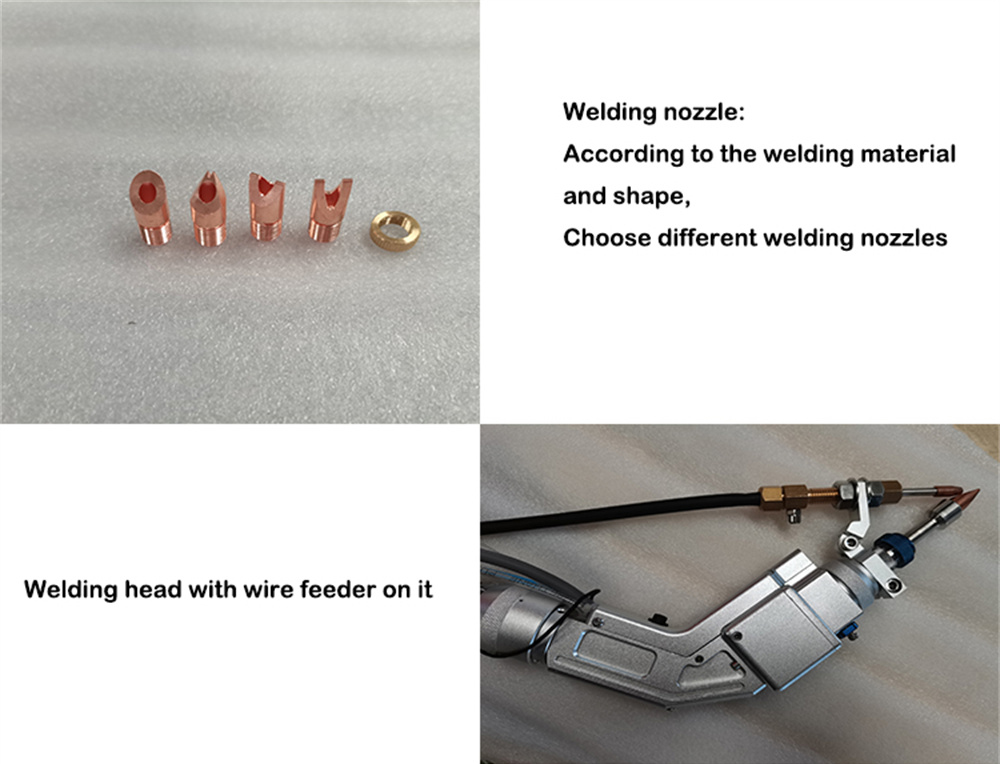

- There are 6 welding modes and multiple welding nozzles to meet different welding needs; it has a safety sensor function, which emits a laser after touching the metal and automatically locks the light when it is removed.

- The machine is equipped with automatic wire-feeder device, which can easily adjust the parameters and provide multiple choices for

customers.

- There are 6 welding modes and multiple welding nozzles to meet different welding needs; it has a safety sensor function, which emits a laser after touching the metal and automatically locks the light when it is removed.

- Dual temperature and dual control, circulating water circuit, can quickly cool the internal pipeline cavity of the welding head,while cooling the laser.

Product Display

Technical parameter

|

Condition |

New |

Core Components |

Laser Source |

|

Usage |

Weld Metal |

Max. Output Power |

2000W |

|

Applicable Material |

Metal |

Cnc Or Not |

Yes |

|

Cooling Mode |

Water Cooling |

Control Software |

Ruida/Qilin |

|

Pulse Width |

50-30000Hz |

Laser Power |

1000w/ 1500w/ 2000w |

|

Weight (Kg) |

300 Kg |

Certification |

Ce, Iso9001 |

|

Core Components |

Fiber Laser Source, Fiber, Handle Laser Welding Head |

Key Selling Points |

High-Accuracy |

|

Function |

Metal Part Laser Welding |

Fiber Length |

≥10m |

|

Applicable Industries |

Hotels, Garment Shops, Building Material Shops |

Core Components |

Laser Supply |

|

Mode Of Operation |

Pulsed |

After Warranty Service |

Online Support |

|

Focal Spot Diameter |

50μm |

Wavelength |

1080 ±3nm |

|

Video Outgoing Inspection |

Provided |

Graphic Format Supported |

Ai, Plt, Dxf, Dwg, Dxp |

|

Place Of Origin |

Jinan,Shandong Province |

Warranty Time |

3 Years |

Main Parts for Machine

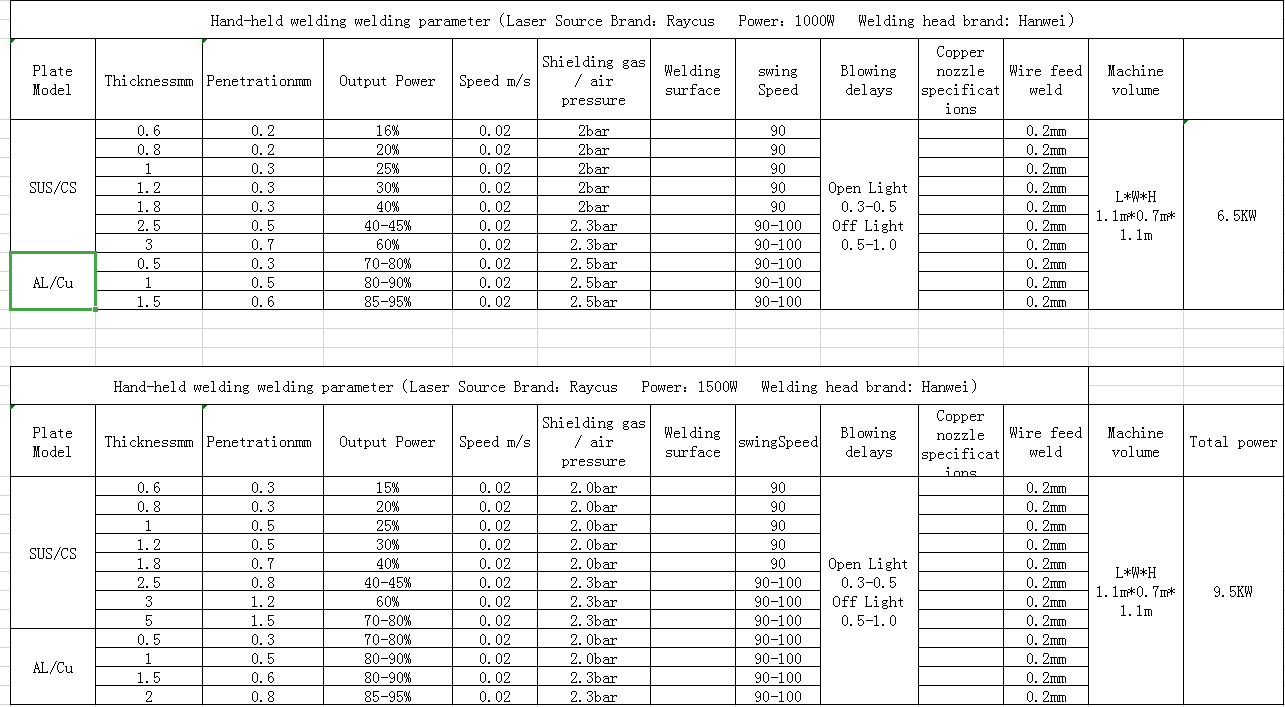

Welding parameter for laser welding machine

Configuration

|

Laser Power |

1000w |

1500W |

2000W |

||||||

|

Welding Material |

Stainless Steel |

Carbon Steel |

Aluminium |

Stainless Steel |

Carbon Steel |

Aluminium |

Stainless Steel |

Carbon Steel |

Aluminium |

|

Welding Thickness(Mm) |

2 |

2 |

1 |

3 |

3 |

2 |

4 |

4 |

3 |

|

Welding Thickness(Inch) |

|

|

|

|

|

|

|

|

|

|

Adaptable Welding Wire |

Welding Wire Diameter 0.8-1.6mm |

||||||||

|

Weld Seam Requirement |

Filler Wire Welding≤1Mm Swinging Welding ≤15% Of Plates Thickness≤0.3Mm |

||||||||

|

Machine Weight |

220Kg |

220Kg |

300Kg |

||||||

|

Machine Size(Mm) |

954X715X1080 |

954X715X1080 |

1155X715X1160 |

||||||

|

Welding Gun Line Length |

10m(The Wire Feed Tube Of The Wire Feeder Is 3 Meters Long) |

||||||||

|

Welding Gun Weight |

Vibrating Mirror Type(Qi Lin):0.9Kg |

||||||||

|

Machine Power |

7Kw |

9Kw |

12Kw |

||||||

|

Language Supported |

Standard: Chinese, English, Korean, Vietnamese, Russian Japanese And Spanish Can Be Customized |

||||||||

|

Voltage And Frequency |

Standard:380V/50Hz Other Voltage And Frequency Is Optional |

||||||||

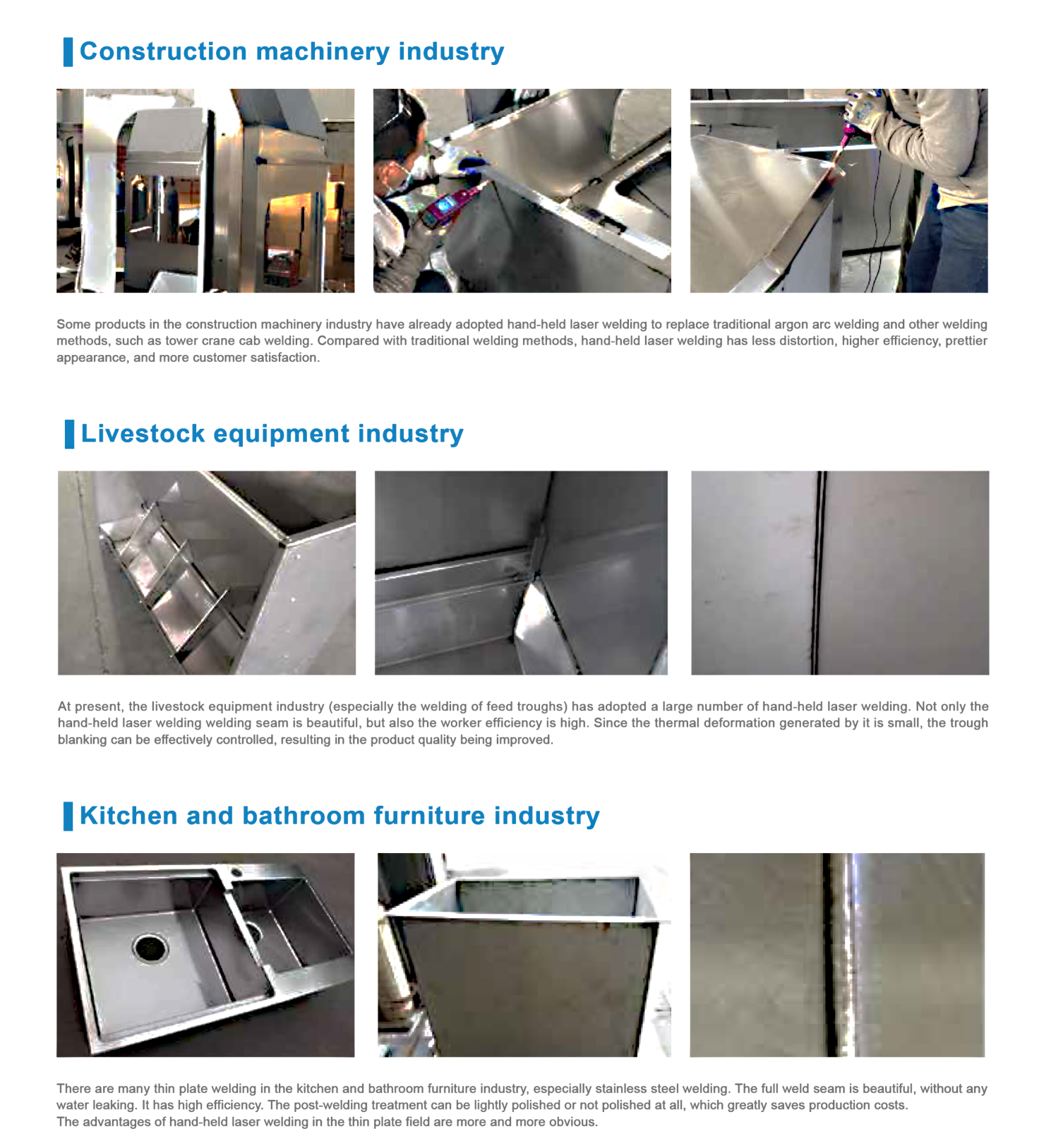

Application industry

Laser welding machines are widely used in the bathroom industry: welding of water pipe joints, reducing joints, tees, valves, and showers. Glasses industry: precision welding of stainless steel, titanium alloy and other materials on the buckle position, outer frame and other positions of glasses. Hardware industry: impeller, kettle, handle, etc., welding of complex stamping parts and casting parts. Laser welding machines are widely used in the automotive industry: engine cylinder gaskets, hydraulic tappet seal welding, spark plug welding, filter welding, etc.

Advantage of laser welding machine

1. Wide welding range: The hand-held welding head is equipped with 5m-10m original optical fiber, which overcomes the limitation of workbench space and can be used for outdoor welding and long-distance welding;

2. Convenient and flexible to use: Hand-held laser welding is equipped with moving pulleys, which is comfortable to hold, and can be adjusted at any time, without the need for fixed-point stations, free and flexible, and suitable for various working environment scenarios.

3. Various welding methods: welding at any angle can be realized: stitch welding, butt welding, vertical welding, flat fillet welding, inner fillet welding, outer fillet welding, etc. welding. Welding at any angle can be achieved. In addition, he can also complete the cutting, welding and cutting can be switched freely, just change the welding copper nozzle to the cutting copper nozzle, which is very convenient.

4. Good welding effect: hand-held laser welding is hot fusion welding. Compared with traditional welding, laser welding has higher energy density and can achieve better welding effect. Trace problems, large welding depth, sufficient melting, firm and reliable, and weld strength reaching or even exceeding the base metal itself, which cannot be guaranteed by ordinary welding machines.

5. Welding seam does not need to be polished: After traditional welding, the welding point needs to be polished to ensure smoothness and not roughness. The hand-held laser welding just reflects more advantages in the processing effect: continuous welding, smooth without fish scales, beautiful without scars, and less subsequent grinding processes.

6. No consumables for welding: In most people’s impressions, the welding operation is “goggles in the left hand and welding wire in the right hand”. However, with the hand-held laser welding machine, the welding can be easily completed, and the material cost in production and processing is reduced.

7. With multiple safety alarms, the welding tip is only effective when the switch is touched when it touches the metal, and the light is automatically locked after the workpiece is removed, and the touch switch has a body temperature sensor. High safety, ensuring the safety of operators during work.

8. Save labor cost: Compared with arc welding, the processing cost can be reduced by about 30%. The operation is simple and easy to learn and quick to learn, and the technical threshold of the operator is not high. Ordinary workers can be employed after a short training, and can easily achieve high-quality welding results.

Product detail pictures:

Related Product Guide:

Our advantages are reduced prices,dynamic product sales workforce,specialized QC,solid factories,superior quality services for Best Price On Laser Printing Machine - Handheld Laser Welding Machine – Rezes , The product will supply to all over the world, such as: Maldives, South Korea, New Zealand, Our company is an international supplier on this kind of merchandise. We supply an amazing selection of high-quality merchandise. Our goal is to delight you with our distinctive collection of mindful items while providing value and excellent service. Our mission is simple: To supply the best items and service to our customers at the lowest prices possible.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!