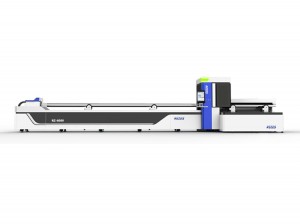

6012 Laser Tube Cutting Machine with Side Mount Chuck-3000W

Product Display

Technical parameter

| Application | Laser Cutting Tube | Applicable Material | Metal Materials |

| Laser Source Brand | Raycus/MAX | Pipes length | 6000mm |

| Chuck diameter | 120mm | Repeated positioning accuracy | ≤±0.02mm |

| Pipe shape | Round tube, square tube, rectangular pipes,special-shaped pipes,other | Electrical Source (Power Demand) | 380V/50Hz/60Hz |

| Graphic Format Supported | AI, PLT, DXF, BMP, Dst, Dwg, DXP,ETC | CNC or Not | Yes |

| Certification | CE, ISO9001 | Cooling system | Water cooling |

| Mode of Operation | Continuous | Feature | Low maintenance |

| Machinery Test Report | Provided | Video outgoing inspection | Provided |

| Place of Origin | Jinan,Shandong Province | Warranty time | 3 years |

Machine Video

The characteristic of 6012 Laser Tube Cutting Machine with Side Mount Chuck :

1.High-power laser: 3000W fiber laser, cutting carbon steel, stainless steel, aluminum alloy and other metal pipes.

2.Large size processing: 6000mm cutting length, 120mm chuck diameter, suitable for various specifications of pipes.

3.Side-mounted chuck design: Improve clamping stability, suitable for long and heavy pipe processing, and ensure high-precision cutting.

4.Automatic focus cutting head: Intelligently sense material thickness, automatically adjust focal length, improve cutting efficiency and quality.

5.Intelligent control system: Support DXF, PLT and other formats, automatic layout optimization, reduce material waste.

6.High speed and high precision: servo motor drive, repeated positioning accuracy can reach ±0.03mm, maximum cutting speed 60m/min.

7.Wide application: suitable for furniture manufacturing, steel structure, automobile manufacturing, pipeline processing, fitness equipment and other industries.

Cutting samples

Service

1. Equipment customization: cutting length, power, chuck size, etc. can be customized according to customer needs.

2. Installation and debugging: provide on-site or remote guidance to ensure the normal operation of the equipment.

3. Technical training: operation training, software use, maintenance, etc., to ensure that customers are proficient in using the equipment.

4. Remote technical support: answer questions online and remotely assist in solving software or operation problems.

5. Spare parts supply: long-term supply of key accessories such as fiber lasers, cutting heads, chucks, etc.

6.Pre-sales consultation and technical support:

We have an experienced team of engineers who can provide customers with professional pre-sales advice and technical support. Whether it's equipment selection, application advice or technical guidance, we can provide fast and efficient help.

7.Quick response after sales

Provide fast after-sales technical support to solve various problems encountered by customers during use.

FAQ

Q: What materials can this equipment cut?

A: It can cut metal pipes such as carbon steel, stainless steel, aluminum alloy, brass, copper, etc.

Q: What is the main processing range of the equipment?

A: Cutting length: 6000mm, chuck diameter: 120mm, suitable for round pipes, square pipes, rectangular pipes and special-shaped pipes.

Q: What are the advantages of side-mounted chucks compared to traditional chucks

A: Side-mounted chucks can clamp long and heavy pipes more stably, avoid pipe shaking, and improve cutting accuracy.

Q: Is the equipment complicated to operate? Do you need professional technicians?

A: Equipped with intelligent software and touch screen operation interface, it is easy to operate and novice can quickly get started after training.

Q: Does this pipe cutting machine support automatic focus?

A: Yes, the automatic focus cutting head can automatically adjust the focal length according to the thickness of the pipe to improve cutting efficiency and quality.

Q: What is the cutting accuracy of the equipment?

A: Positioning accuracy ≤±0.05mm, repeat positioning accuracy ≤±0.03mm, ensuring high-precision cutting.

Q: What should be paid attention to in the daily maintenance of the equipment?

A: The main maintenance includes:

Lens cleaning (to prevent light loss)

Cooling system inspection (to keep the water circulation normal)

Gas system maintenance (to ensure the stability of cutting gas)

Regular inspection of chuck and guide rail (to avoid mechanical wear)

Q: Do you provide installation and training services?

A: Provide installation and debugging, technical training to ensure that customers can operate the equipment correctly.

Q: How long is the warranty period? How about after-sales service?

A: Three years for the whole machine, 1 year for the laser, and provide remote support, maintenance services, accessories replacement and other after-sales support.