6000W Continuous laser cleaning machine with 500x500mm scan area

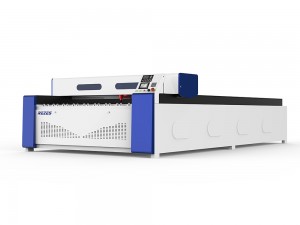

Product Display

Technical parameter

| Application | Laser Cleaning | Applicable Material | Metal materials |

| Laser Source Brand | Raycus | CNC or Not | Yes |

| Fiber interface | QBH | Wavelength range | 1070±20nm |

| Rated power | ≤6KW | Collimation focal length | 75mm |

| Focus focal length | 1500mm | Scan width | 200~500mm |

| Scan speed | 40000mm/s | Auxiliary gas pressure | ≥0.5~0.8Mpa |

| Certification | CE, ISO9001 | Cooling system | Water cooling |

| Mode of Operation | Continuous | Feature | Low maintenance |

| Machinery Test Report | Provided | Video outgoing inspection | Provided |

| Place of Origin | Jinan,Shandong Province | Warranty time | 3 years |

Machine Video

The characteristic of 6000W High Power Laser Cleaning Machine

1. Efficient and powerful cleaning

Ultra-high power output: 6000W continuous laser can provide enough energy in a short time to quickly remove thick oxide layers, stubborn coatings and heavy pollutants.

Large-area application: suitable for industrial-grade large-area cleaning operations to improve overall production efficiency.

2. Intelligent control of laser parameters

Adjustable laser energy density: By adjusting the laser power, scanning speed and focusing parameters, the cleaning solution can be customized according to different pollutants and material characteristics.

Intelligent control system: supports real-time monitoring and feedback of parameters to ensure stable equipment operation during the cleaning process and optimize the cleaning effect.

3. Environmentally friendly cleaning technology

No chemical reagents: No chemical substances are required during the cleaning process, avoiding chemical waste liquid and secondary pollution.

Low environmental load: The cleaning process mainly relies on laser action, and no additional consumables are required, which meets the requirements of green environmental protection.

4. Automated integration and convenient operation

High automation level: The equipment supports integration with robots, CNC systems or automated production lines to meet the needs of unmanned operations.

Modular design: compact structure, easy installation and maintenance, and can be flexibly adapted to different industrial environments and work scenarios.

5. Low maintenance cost and long life

Stable and durable: The fiber laser design focuses on long-term stable operation, and equipment maintenance is mainly concentrated on the daily maintenance of the water cooling system.

Economical and efficient: While ensuring high cleaning efficiency, it reduces long-term operating costs and is suitable for large-scale industrial applications.

Service

1.Customized services:

We provide customized fiber laser cleaning machines, custom designed and manufactured according to customer needs. Whether it is cleaning content, material type or processing speed, we can adjust and optimize it according to the customer's specific requirements.

2.Pre-sales consultation and technical support:

We have an experienced team of engineers who can provide customers with professional pre-sales advice and technical support. Whether it's equipment selection, application advice or technical guidance, we can provide fast and efficient help.

3.Quick response after sales

Provide fast after-sales technical support to solve various problems encountered by customers during use.

FAQ

Q: What is its main working principle?

A: The equipment uses continuous laser irradiation to make the pollutants absorb laser energy and produce thermal effects, causing the pollutants to melt, vaporize or peel off, thereby achieving surface cleaning.

Q: What effects will the laser cleaning process have on the substrate?

A: Since continuous lasers have a strong thermal effect, the surface of the substrate may be slightly melted or heat-lost during the cleaning process. Therefore, the parameters must be strictly controlled during operation to balance the cleaning effect and substrate protection.

Q: How to adjust the laser parameters to balance the cleaning effect and substrate safety?

A: The equipment uses an intelligent control system that can adjust the laser energy density, scanning speed and focusing parameters. Users need to select appropriate cleaning parameters according to different materials and pollution levels to ensure sufficient cleaning while minimizing heat loss to the substrate.

Q: What industrial fields is this equipment mainly suitable for?

A: 6000W continuous laser cleaning machines are widely used in steel, shipbuilding, rail transportation, petrochemicals, aerospace and mold cleaning, and are particularly suitable for heavy pollution or large-area cleaning operations.

Q: What safety precautions should be taken when using it?

A: During use, operators should wear protective equipment (such as laser protective glasses, protective clothing, etc.), and strictly abide by the equipment operating procedures to prevent risks such as laser radiation damage and equipment overheating.

Q: What are the maintenance requirements and cycles of the equipment?

A: The main maintenance work focuses on the inspection and maintenance of the water cooling system and laser fiber. Regularly checking the coolant, cleaning the optical components and keeping the outside of the equipment clean will help extend the service life of the equipment and ensure stable operation.

Q: What are the environmental advantages of the equipment

A: Laser cleaning does not require the use of chemical cleaning agents, and there is no chemical waste liquid discharge during the process, which meets environmental protection requirements; at the same time, no consumables are required, which can reduce the risk of secondary pollution.

Q: Does the equipment support automated production line integration?

A: Yes, the 6000W continuous laser cleaning machine is equipped with an intelligent control system, which can be seamlessly connected with robots, CNC systems or automated production lines to achieve efficient unmanned operations.

Q: Can the cleaning solution be customized according to different needs?

A: Yes. The equipment supports multi-parameter control and modular design. Customers can customize exclusive cleaning solutions according to different materials, pollution types and production requirements to achieve the best cleaning effect.