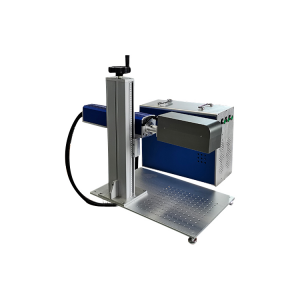

3D UV Laser Marking And Engraving Machine

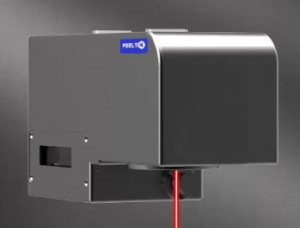

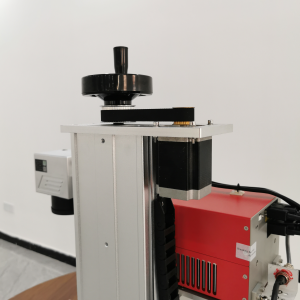

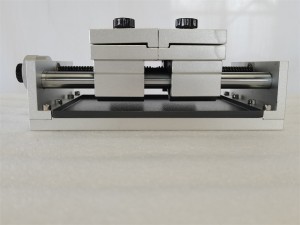

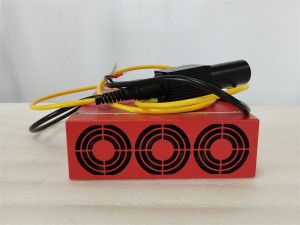

Product Display

Technical parameter

| Application | Laser Marking | Applicable Material | Metals and non-metals |

| Laser Source Brand | JPT/HURAY/INNGU | Marking Area | 110*110mm/175*175mm/200*200mm/

300*300mm/other |

| Mini Line Width | 0.001mm | Min Character | 0.1mm |

| Laser Repetition Frequency | 20KHz-100KHz(adjustable) | Marking Depth | 0~0.5mm(subject to material) |

| Graphic Format Supported | AI, PLT, DXF, BMP, Dst, Dwg, DXP,ETC | CNC or Not | Yes |

| Wavelength | 1064nm ±10nm | Certification | CE, ISO9001 |

| Mode of Operation | Manual or Automatic | Working Accuracy | ±0.001mm |

| marking speed | 10000mm/s | Cooling system | Air cooling/ water cooling |

| Control System | JCZ | Software | Ezcad software |

| Mode of Operation | Continuous | Feature | Low maintenance |

| Configuration | Overall design | Positioning method | Double red light positioning |

| Machinery Test Report | Provided | Video outgoing inspection | Provided |

| Place of Origin | Jinan,Shandong Province | Warranty time | 3 years |

Technical parameter

The characteristic of 3D UV laser marking machine

1.High-precision marking: UV laser has a short wavelength and a very small spot, which can achieve ultra-fine marking effects on complex surfaces and subtle parts, and is suitable for processing small-sized parts.

2.Cold processing technology: Due to the high photon energy of UV laser, it can directly destroy the molecular bonds of the material and almost no thermal impact, thus avoiding problems such as material deformation and burning.

3.Wide range of applicable materials: 3D UV laser marking machine can mark metal and non-metal materials, including plastics, glass, ceramics, silicon wafers, etc., especially suitable for marking heat-sensitive materials without deformation or burns.

4.Flexible three-dimensional marking: The equipment can mark on irregular or curved workpieces, suitable for various complex three-dimensional surface processing needs.

5.Environmental protection: UV laser marking uses "cold processing" technology, which can reduce the impact on the environment, no consumables, and no pollution during the marking process.

Marking samples

Service

1.Customized services:

We provide customized UV laser marking machines, custom designed and manufactured according to customer needs. Whether it is marking content, material type or processing speed, we can adjust and optimize it according to the customer's specific requirements.

2.Pre-sales consultation and technical support:

We have an experienced team of engineers who can provide customers with professional pre-sales advice and technical support. Whether it's equipment selection, application advice or technical guidance, we can provide fast and efficient help.

3.Quick response after sales

Provide fast after-sales technical support to solve various problems encountered by customers during use.

FAQ

Q: What materials are UV laser marking machines suitable for?

A: UV laser marking machines are suitable for a variety of materials, including plastics, metals, rubber, ceramics, glass, etc., and can mark, etch or cut these materials with high precision.

Q.What is the speed of UV laser marking machine?

A: UV laser marking machines process quickly, but the actual speed depends on the content of the mark, the type of material, the depth of the mark, etc.

Q: What safety measures are required for UV laser marking machines?

A: UV laser marking machines must be equipped with appropriate safety measures, such as protective covers, emergency stop buttons, etc., to ensure the safety of operators. Operators must use appropriate personal protective equipment such as goggles.

Q:What are the application fields of UV laser marking machines?

A:UV laser marking machines are widely used in electronics, medical equipment, auto parts, jewelry, packaging and other fields. It can achieve high-precision and high-efficiency marking to meet the needs of different industries.