100W DAVI Co2 Laser Marking And Engraving Machine

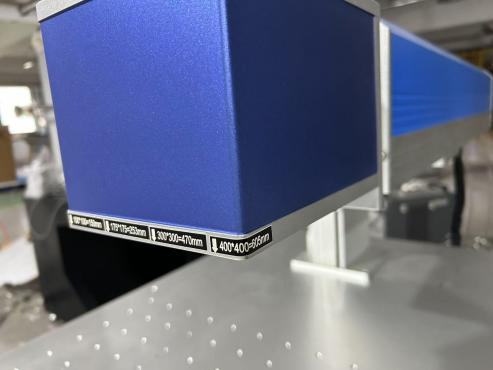

Product Display

Technical parameter

| Application | Laser Marking | Applicable Material | Non-metals |

| Laser Source Brand | DAVI | Marking Area | 110*110mm/175*175mm/200*200mm/300*300mm/other |

| Graphic Format Supported | AI, PLT, DXF, BMP, Dst, Dwg, DXP,ETC | CNC or Not | Yes |

| Wavelength | 10.3-10.8μm | M²-beam quality | ﹤1.5 |

| Average power range | 10-100W | Pulse frequency | 0-100kHz |

| Pulse energy range | 5-200mJ | Power stability | ﹤±10% |

| Beam pointing stability | ﹤200μrad | Beam roundness | ﹤1.2:1 |

| Beam diameter (1/e²) | 2.2±0.6mm | Beam divergence | ﹤9.0mrad |

| Peak effective power | 250W | Pulse rise and fall time | ﹤90 |

| Certification | CE, ISO9001 | Cooling system | Water cooling |

| Mode of Operation | Continuous | Feature | Low maintenance |

| Machinery Test Report | Provided | Video outgoing inspection | Provided |

| Place of Origin | Jinan,Shandong Province | Warranty time | 3 years |

Machine Video

The characteristic of 100W Co2 laser marking machine :

1. Wide range of applications: CO2 laser marking machines can perform high-precision marking on a variety of non-metallic materials, including wood, leather, paper, plastic, rubber, acrylic, glass, etc., suitable for the needs of various industries.

2. High-precision marking: The laser marking machine uses a fine laser beam for marking, which can achieve high-resolution and detailed marking. It is suitable for making small and complex patterns and texts, especially for QR codes, barcodes, LOGO and other logos.

3. Non-contact processing: Laser marking is a non-contact processing, which will not produce any mechanical pressure or deformation on the surface of the material, which makes it suitable for delicate and complex parts and avoids physical wear.

4. Permanent marking: Laser marking is to form a mark by high-temperature ablation of the material surface, which is permanent and will not fade or be damaged due to time, friction or other external factors, ensuring that the mark is durable.

5. No consumables: CO2 laser marking machine does not need to use any ink or chemical reagents, and it is completely marked by laser technology, which reduces material consumption and meets environmental protection requirements.

6. Efficient and fast: CO2 laser marking machine has high working efficiency and can quickly complete large-scale marking work, which is very suitable for large-scale production and efficient working environment.

7. Low heat-affected zone: The laser beam heat-affected zone of CO2 laser marking machine is small, which can perform fine marking on thinner materials while avoiding overheating and deformation of materials.

Marking samples

Service

1.Customized services:

We provide customized Co2 laser marking machines, custom designed and manufactured according to customer needs. Whether it is marking content, material type or processing speed, we can adjust and optimize it according to the customer's specific requirements.

2.Pre-sales consultation and technical support:

We have an experienced team of engineers who can provide customers with professional pre-sales advice and technical support. Whether it's equipment selection, application advice or technical guidance, we can provide fast and efficient help.

3.Quick response after sales

Provide fast after-sales technical support to solve various problems encountered by customers during use.

FAQ

Q: How deep is the marking depth of the CO2 laser marking machine?

A: The marking depth of the CO2 laser marking machine depends on the type of material and the laser power. Generally speaking, it is suitable for shallow marking, but for harder materials, the marking depth will be relatively shallow. High-power lasers can achieve a certain depth of engraving.

Q: How does the CO2 laser marking machine ensure the durability of the marking?

A: The CO2 laser marking machine uses a high-temperature laser beam to ablate the surface of the material to form a mark. The marking is permanent, wear-resistant, and fade-resistant, and it is not easy to disappear due to external factors.

Q: What types of patterns can the CO2 laser marking machine mark?

A: The CO2 laser marking machine can mark various patterns, texts, QR codes, barcodes, serial numbers, company logos, etc., and is particularly suitable for applications that require detailed and precise marking.

Q: Is the maintenance of the CO2 laser marking machine complicated?

A: The maintenance of the CO2 laser marking machine is relatively simple. It mainly requires regular cleaning of the optical lens, inspection of the laser tube and the heat dissipation system to ensure the normal operation of the machine. Proper daily maintenance can extend the service life of the equipment.

Q: Is the cost of CO2 laser marking machine high?

A: Compared with traditional marking methods (such as inkjet printing), the initial investment of CO2 laser marking machine is higher, but since it does not consume consumables such as ink and paper, the overall cost is relatively low in the long run.

Q: What additional accessories or consumables are required for CO2 laser marking machine?

A: CO2 laser marking machine usually requires some accessories such as optical lenses, laser tubes and cooling systems. In addition, it may also require a suitable power supply and air compressor to ensure the stable operation of the machine.

Q: How to choose the right CO2 laser marking machine model?

A: When choosing the right model, you need to consider factors such as marking materials, marking speed, accuracy requirements, equipment power and budget. If you are not sure, you can consult the supplier to make recommendations based on specific needs.